The demands placed on industrial cleaning systems are constantly increasing - especially in the aerospace industry. Maximum technical cleanliness, absolute process reliability and reproducible results are no longer optional features, but indispensable standards. Karl Roll GmbH & Co KG, a specialist in aqueous and solvent-based parts cleaning systems, is currently implementing an unusual project: the simultaneous construction of four identical REF systems (aqueous single-chamber flooding systems), tailor-made for a customer in the aerospace industry.

The engineers are relying on a tried-and-tested but consistently refined technology: the pressure swing process, which is based on the targeted use of cavitation - a physical effect that was successfully used in the automotive sector over two decades ago. "We used the pressure change process back in the 2000s to clean the fuel lines in the common-rail diesel system - it was a real pioneering step at the time. Today, we are building on this experience, but with completely new technical possibilities," explains Frank Bührle, Technical Managing Director of Karl Roll.

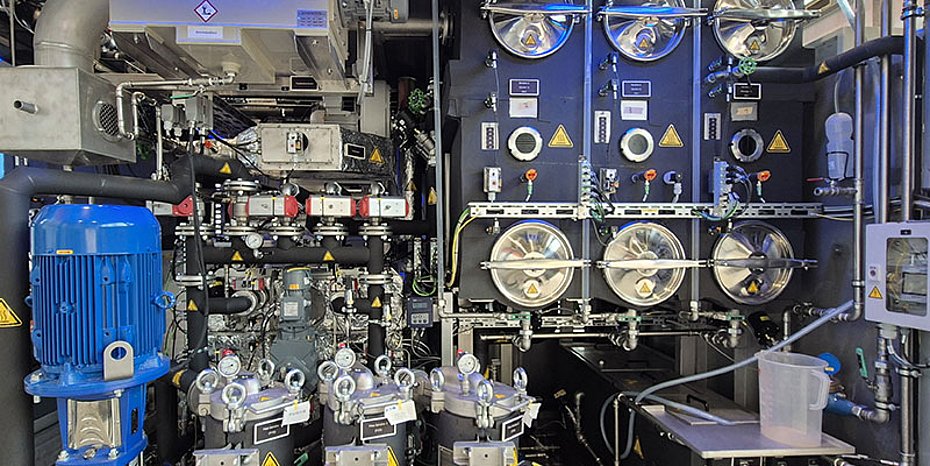

Four REF systems for the aviation industry

The four REF systems were not built for internal standardization purposes, but in response to a specific customer order. An internationally active company from the aviation industry made a conscious decision in favor of the REF concept - and ordered four identical systems. The reasons for this are obvious: in addition to the proven cleaning technology, the reliability, reproducibility and modular design, which can be flexibly integrated into different production environments, were convincing.

"When a customer from a safety-critical sector such as aviation orders four identical systems, this is not only a sign of trust, but also a clear statement: our technology and process reliability are convincing," says Oberauer.

REF in series - proven cleaning technology at a new level

For those involved in the project at Karl Roll, this multiple implementation is a particularly pleasing order - not because four systems in series is an exception, but because it underlines the customer's confidence in the performance and quality of REF technology. "Multiple orders like this are common practice for us," says Roland Schmidt, Sales Manager at Karl Roll. "But it's always something special when a customer orders four identical systems at the same time - it shows how convincing our technology and process reliability are."

Each of the four systems is based on the same basic technical structure, but the implementation shows Karl Roll's typical signature: sophisticated control concepts, energy-efficient components, intelligent process control and a high degree of ease of maintenance. The combination of mechanical expertise and digital control ensures stable processes and consistently high cleaning quality - even with complex component geometries.

Conclusion: Technology with depth - ready for the future

With the REF system, Karl Roll demonstrates how technological experience and continuous development can go hand in hand. The pressure change process has already proven to be a powerful tool in the past - now it is part of a future-oriented system that is precisely tailored to the requirements of industries with the highest quality standards.

"We are building on proven technology, but we are not resting on our laurels," emphasizes Schmidt. "Our aim is to supply cleaning systems that not only work today - but also set standards tomorrow." (OM-6/25)

Excursus: The pressure change process - cleaning with cavitation

The pressure change process is a physically based cleaning process that relies specifically on the cavitation of steam bubbles in liquids. This effect - known from shipping or hydraulics, for example - is used here in a controlled manner to remove particles, residues and contamination, even in the finest cavities and boreholes.

A vacuum is initially generated in a working chamber filled with cleaning fluid. This causes small vapor bubbles to form on surfaces and in narrow geometries. The bubbles are created by the negative pressure, which falls below the local boiling point of the liquid. If the pressure is then suddenly increased, these bubbles implode - creating a local micro-pressure surge that releases powerful cleaning forces without mechanically stressing the components.

This type of cavitation has a targeted effect on adhering particles, residues or production media - in places where conventional methods often reach their limits: in blind holes, internal structures or capillary channels. In contrast to ultrasonic cleaning, where cavitation is generated by sound waves, here it is purely pressure-induced. This enables a very uniform, reproducible cleaning effect - even with geometries that are difficult to access and deep internal contamination.

Back in the early 2000s, Karl Roll successfully used the process in the automotive industry to clean common rail petrol lines. Today's REF systems take this proven technology to a new level of precision - tailor-made for industrial applications where the highest standards of cleanliness, precision and quality are required.

"The principle is not new - but the way we use it today is state-of-the-art."

- Tobias Oberauer, Commercial Managing Director of Karl Roll.

Contact

Karl Roll GmbH & Co. KG

Kanalstraße 30

75417 Mühlacker-Enzberg (Germany)

Phone: +49 (0)70 41 802-0

E-mail: verkauf@karl-roll.de

www.karl-roll.de

About Karl Roll

Karl Roll GmbH & Co KG is one of Europe's market leaders in the field of industrial parts cleaning. The Roll product range includes all available techniques for the wet cleaning of components: Proven solvent systems, both for hydrocarbon cleaners, modified alcohol and perchloroethylene, as well as a wide selection of aqueous systems. In addition to a standardized type program with a wide range of accessories, Karl Roll also constantly develops and manufactures special designs.