In line with the changing and industry-specific requirements in industrial parts cleaning, Ecoclean GmbH has diversified its product and service portfolio more strongly. This includes cleaning equipment and systems specially designed for so-called high-purity cleaning applications, with which extremely high cleanliness requirements for metallic and optical components can be met in a process-safe manner. Such components are required, among others, by manufacturers of production equipment for the semiconductor industry, in precision optics, laser, measurement, analysis and high-vacuum technology. It was therefore a logical and consistent decision to provide customers from these market segments with appropriate capacities and technologies for cleaning tests under ultra-clean conditions in the cleanroom. This was implemented with the new High Purity Test Center at the production site in Dettingen unter Teck, in which Ecoclean invested around four million euros. It was officially inaugurated at the end of November 2022.

More than an alternative to in-house trials

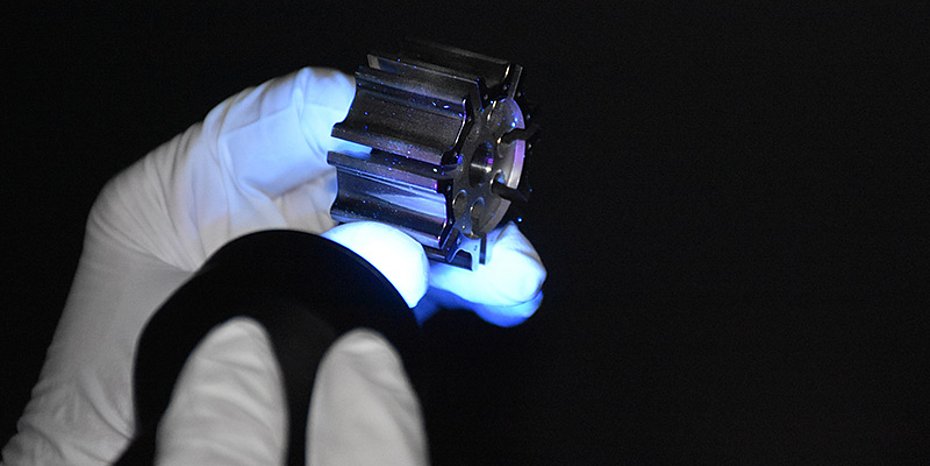

The new Test Center has a total of five cleaning systems with equipment specifically required for high-purity cleaning. They cover the technologies, media and processes used in wet-chemical component cleaning, for example ultrasound, injection flood washing, plasma cleaning, pulsed pressure cleaning (PPC) and ultrasound plus.

For customers who manufacture precision components for high-purity applications, the ability to conduct cleaning tests in the Ecoclean Test Center offers various advantages. For new parts, for example, elaborate process validation and cleaning tests are usually required. These would put a strain on in-house cleaning facilities, which are usually fully utilized and validated. The cleaning process and process parameters, for example washing mechanics, chemistry, water qualities, cycle times and cleaning results, can be designed in the best possible way for the respective component, independently of any processes already in place in the company. The tests make it easier to estimate the required cleaning process and result in advance, which minimizes the risk for the team of customer and equipment manufacturer. In addition, tests and feasibility studies on the cleanability of new precision components can be carried out without having to intervene in validated production processes. Last but not least, customers can be supported by job cleaning if required.

Equipped for pre and final cleaning with the highest requirements

The new test center has two cleaning areas of different cleanliness classes for this purpose. The first is located in a clean room that incorporates a solvent chamber cleaning system with integrated low-pressure plasma cleaning and a chamber system for aqueous media. This area is used for pre-cleaning to prepare parts for final cleaning in the cleanroom. It is also suitable for meeting the higher cleanliness requirements of many classic ultra-fine cleaning tasks from industries such as sensor technology, aviation, e-mobility and the coating industry.

The final cleaning area is housed in a validated ISO 7 class cleanroom with ISO 6 zones. The equipment includes a solvent chamber system, a chamber system for water-based media, and a multi-bath ultrasonic cleaning system with nine wet and two dry stations. Here, various ultrasonic frequencies, cleaning chemicals, PPC, and passivation, among others, can be tested. Various options - also in combination - are also available for drying.

The treatment solutions for osmosis (RO), de-ionized (DI) and ultra-pure water (UPW) integrated in the new technology center allow the use of all water qualities used in ultra-fine and high-purity cleaning. This equipment allows extremely high cleanliness requirements to be met, for example corresponding to grades 2 and 1. Since all the systems are networked via the Ecoclean Connect cloud solution, the data from the systems and cleaning tests are available digitally. The test center is equipped with various measuring technologies for checking the cleaning results achieved. A special packaging station for the cleaned products is also integrated. (OM-12/22)

Read also our news article about it: Ecoclean opened new High-Purity Test Center in Dettingen/Teck

Contact

Ecoclean GmbH

Mühlenstraße 12

70794 Filderstadt (Germany)

www.ecoclean-group.net

About Ecoclean

The SBS Ecoclean Group develops, produces and sells future-oriented equipment, systems and services for industrial component cleaning and surface treatment. These solutions, which are world leaders, support companies around the globe in producing efficiently and sustainably in high quality. The group of companies is represented in nine countries with twelve locations worldwide and employs more than 900 people.