Efficient and sustainable component cleaning for demanding high-tech components

In most cases, the increased cleanliness requirements for high-tech components can no longer be met with conventional cleaning systems. Optimally adapted solutions for precision and high-purity applications are required here.

Whether it's a millimeter-small fastener, complex precision optics or meter-sized plant component, the cleanliness requirements for high-tech components are becoming increasingly demanding and stringent in numerous industries. While the specific specifications vary depending on the component, industry and application, conventional cleaning equipment usually cannot achieve the result required for stable product quality. As an experienced supplier of solutions for precision and high-purity cleaning for many years, Ecoclean is consistently driving forward the development of cleaning equipment, methods and processes for this sector, including specially designed equipment packages.

Industries such as the semiconductor supply industry, the optical and optoelectronic industry, thin-film technology, vacuum, laser and analysis technology, and medical technology are all sectors in which the demands on the performance and reliability of components and parts have increased enormously and continue to do so. This has an impact on component cleaning.

Higher cleanliness requirements due to new products and processes

In the case of components for semiconductor production equipment, new developments in wafer steppers and scanners for EUV lithography, among other things, are not only resulting in increasingly geometrically complex mechanical components, they are also becoming larger and heavier. Today, the diameters of these workpieces range from one millimeter to more than one meter, with the "scissors" continuously moving further apart. In parallel, the variety of materials is increasing. In addition, specifications regarding particulate, film chemical, organic and inorganic cleanliness are becoming increasingly stringent.

The situation is similar for vacuum technology components used in the UHV, XHV and UCV range, for example in high-power laser systems, high-tech measuring and analysis equipment. In the case of precision optics such as mirrors, lenses and prisms, as well as micro-optical parts, more complex geometries and changed materials also result in new and challenging cleaning tasks. In coating technology, increasingly efficient processes require highly clean surfaces. And this is true regardless of whether components such as machine tools, automotive components and optical products are to be cleaned before or after coating.

Needs-based definition of cleanliness

For component cleaning, this results in demanding tasks that extend over the entire production process. The cleanliness requirements vary depending on the product, area of application and company. Particulate cleanliness specifications, which in the case of precision and high-purity applications extend into the nanometer range, are usually defined in terms of surface cleanliness class (ORC). The specifications for the required film-chemical, organic and inorganic surface cleanliness are usually defined by individual specifications or factory standards, for example outgassing rates that are evaluated by mass spectrometers.

In order to solve these tasks efficiently and sustainably, comprehensive technological know-how as well as knowledge of the applications and physical interrelationships are required. As an experienced full-range supplier of future-oriented solutions for precision and high-purity cleaning, Ecoclean has both. This ensures cleaning solutions designed and equipped to meet requirements, with which defined cleanliness specifications up to the highest current requirements (e.g. Grade 1) can be stably achieved.

Selection of the right cleaning process and plant technology

Essential criteria for the selection of the most suitable cleaning process and plant technology are the cleanliness to be achieved, the contamination to be removed, and the material and geometry of the component. On this basis, it is possible to determine which and how many process steps are required with which cleaning medium and which mechanics. Aspects such as the quality of the rinsing medium and the drying technology are included in this consideration, as are the cleanliness-compliant handling of parts and the ambient conditions, for example connection or integration into a cleanroom.

If the specification is defined as "oil- and grease-free", for example Grade 4, cost-efficient and compact full-vacuum single-chamber systems are available whose system technology, media supply and preparation, and design have been specially adapted for high-end cleaning applications. With these systems, which are operated with environmentally compatible solvents or water-based cleaning agents, it is possible to achieve stable results in line with requirements, even for geometrically complex components. Process options that can be combined in almost any way, such as injection flood washing, spray, high-pressure, immersion, ultrasonic or megasonic and plasma cleaning, as well as Ultrasonic Plus or Pulsed Pressure Cleaning (PPC), contribute to this. Often, a modified alcohol (partially polar solvent) is used for these applications due to the media-related plus points, such as the possibility of cleaning different materials. The limit of the requirements that can be achieved with these systems is, for example, Grade 2.

Especially for large parts, chamber cleaning systems offer advantages due to the process mechanics concentrated in the working chamber, for example PPC, ultrasonic or megasonic and injection flood guards. In order to be able to use these also with grade 2 or corresponding cleanliness specifications, Ecoclean manufactures with the EcoCvela double chamber systems for cleaning with water-based media. In addition to the special high-purity equipment, completely separate media circuits for cleaning and rinsing ensure that the defined cleaning result is achieved reliably and reproducibly.

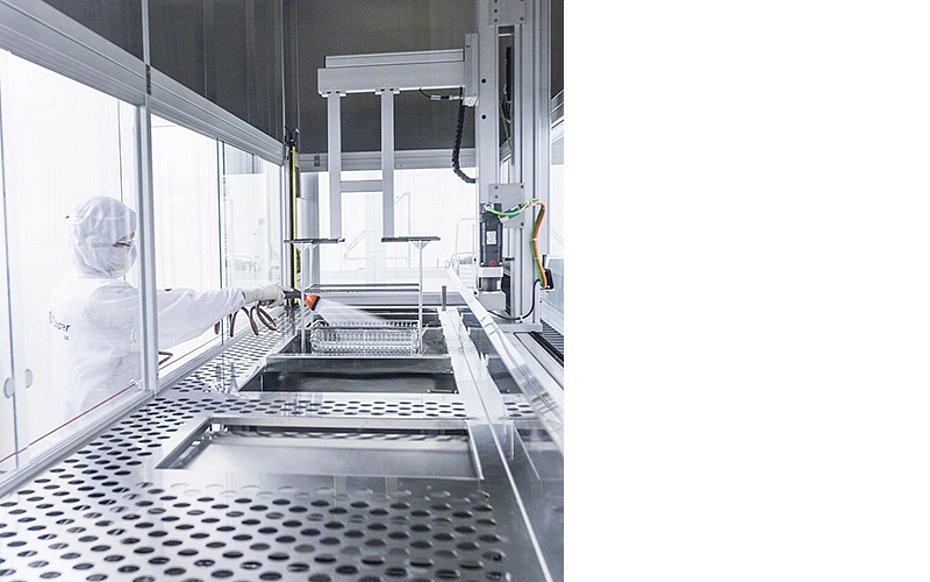

If, due to a large variety of materials and/or high throughput requirements or cleanliness specifications corresponding to Grade 1, for example, the cleaning tasks cannot be solved with a chamber system that can be supplied at relatively short notice, a multi-bath ultrasonic cleaning system is required. With the solutions of the UCMSmartLine or UCMPerformanceLine model series consisting of standardized modules, the SBS Ecoclean Group also offers efficient solutions in this area. Thanks to the electrical and control technology integrated in the modules for the process steps cleaning, rinsing, drying, loading and unloading as well as the equipment with a flexible transport system, they allow easy adaptation to the respective task and can be expanded as required. Individually designed multi-bath ultrasonic cleaning systems such as the UCM HighLine are usually used in high-end applications, for example in the semiconductor supply industry, laser and optical industries.

Process development and design in the test center

Which system concept is the right one from the point of view of cleanliness and economy is determined by cleaning tests with original components or test specimens. Ecoclean has appropriate High Purity Test Centers for this purpose. This enables the product-specific development of cleaning processes and process parameters, which can be stored as programs in the system control. This ensures that each part is treated with the validated process parameters and that the required purity is achieved in a stable and reproducible manner. In addition, all relevant process parameters can be monitored, documented and transferred to higher-level systems. (OM-2/23)

Contact

Ecoclean GmbH

Mühlenstraße 12

70794 Filderstadt (Germany)

www.ecoclean-group.net

About Ecoclean

The SBS Ecoclean Group develops, produces and sells future-oriented equipment, systems and services for industrial component cleaning and surface treatment. These solutions, which are world leaders, support companies around the globe in producing efficiently and sustainably in high quality. The group of companies is represented in nine countries with twelve locations worldwide and employs more than 900 people.