The core business of the Swiss Hug Oberflächentechnik AG includes pickling, electropolishing and passivation of stainless steel. The company has over 40 years of experience in stainless steel finishing. The surface treatments are designed for a wide range of products, from simple parts to high-quality products for medical technology, the pharmaceutical industry and sterile technology.

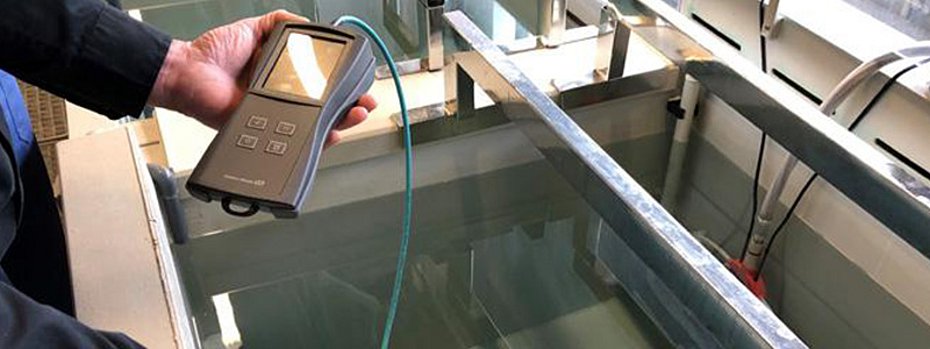

With the portable Teqwave T from the supplier Endress+Hauser, Hug Oberflächentechnik AG now has a new, flexible solution for monitoring its passivation and degreasing baths. Using special sound waves, the Teqwave creates an acoustic "fingerprint" of the high-quality concentration solution. The Teqwave thus precisely measures the concentration and density of the liquid in the treatment process.

Simple real-time measurement

For absolute process quality, the Teqwave measures in real time and the treatment baths can thus be readjusted at any time. Now all employees of Hug Oberflächentechnik AG can operate the Teqwave easily and efficiently. This ensures consistent measurement regardless of the specialist. With the automatic documentation, the susceptibility to errors due to manual noting of the measured concentration values is practically eliminated.

The challenge

Previously, the concentration in the baths was indexed daily by means of a hydrometer, also known as a hydrometer or spindle. This also included the documentation of the concentration values, which are crucial for achieving the desired process stability. The previous measurement and documentation was very time-consuming and could only be carried out by a specialist. Both manual reading and documentation were prone to errors.

The solution

The Teqwave T from Endress+Hauser convinced Hug Oberflächentechnik AG with its smart, highly flexible solution for mobile concentration measurement. With just one measuring device, concentration values can be monitored at numerous measuring points. This allows product quality to be maximized - with minimal operating costs. The Teqwave T mobile transmitter can operate for up to 8 hours without an external power supply and can be adapted to production requirements thanks to its customizable app concept and preconfigured measuring points. "The Teqwave T from Endress+Hauser has fully met our expectations in terms of functionality, performance and technical design," says Marcel Hug, Managing Director of Hug Oberflächentechnik AG. (OM-08/22)

Surface technology solutions from Hug Oberflächentechnik

The passivation solution used is a high-quality product based on citric acid or nitric acid. It is used for efficient passivation of stainless steels.

The degreasing solution is an alkaline cleaner with a complex composition. Among other things, it contains surface-active substances and inhibitors that prevent attack on the component surface. This type of surface cleaning is the most commonly used cleaning process in the metalworking industry.

Contact

Endress+Hauser (Deutschland) GmbH + Co. KG

Colmarer Str. 6

79576 Weil am Rhein (Germany)

Phone +49 (0)7621 975-01

E-mail: info.de@endress.com

www.de.endress.com

About Endress+Hauser Germany

Endress+Hauser is a leading global supplier of measuring instruments, services and solutions for industrial process engineering. The company offers process solutions for flow, level, pressure and temperature measurement, for analytical measurements as well as measurement recording and digital communication, optimizing processes in terms of economic efficiency, safety and environmental impact.