parts2clean 2025: Demand-oriented, efficient and sustainable parts cleaning

Parts cleaning is more than just a production step, because "cleanliness" must be the focus throughout the entire production process. At the parts2clean 2025 trade fair, solutions will be presented for efficient and sustainable cleaning in line with requirements.

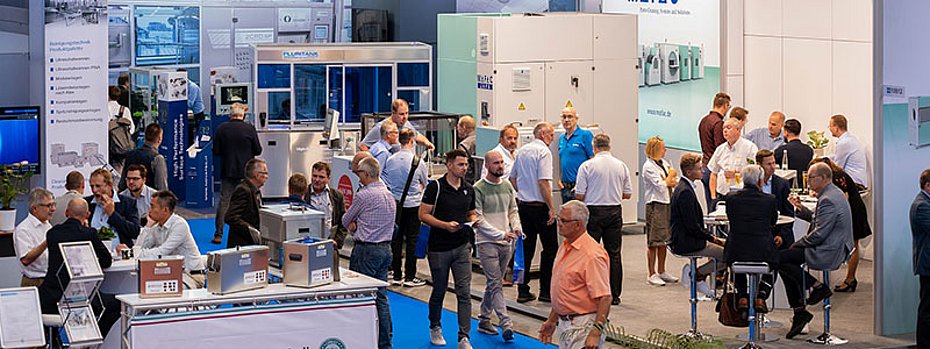

Large areas of industry are now concentrating on manufacturing sophisticated products for growth sectors. This is accompanied by higher demands on technical cleanliness, which cannot be met with a cleaning process at the end of production. Instead, the focus must be on the quality criterion of "cleanliness" throughout the entire production process. The exhibitors and the supporting program at parts2clean will provide information on which aspects need to be taken into account and how cleaning tasks along the production chain can be solved not only in line with requirements, but also efficiently and in a resource-saving manner. The 21st leading international trade fair for industrial parts and surface cleaning will take place from October 7 to 9, 2025 at the Stuttgart Exhibition Centre (Germany).

Due to the technological upheavals, more and more companies are rethinking their product range and increasingly focusing on the production of sophisticated components with higher added value for growth and high-tech industries. These include aerospace, measurement and analysis technology, medical and pharmaceutical technology, sensor technology, new mobility, electronics, microsystems technology, the defense industry, vacuum technology and the semiconductor industry, including its suppliers. "In these industrial sectors, components have to meet very high standards in terms of performance, quality and reliability," explains Ramtin Randjbar-Moshtaghin, Project Director at Deutsche Messe AG. "The requirements for particulate and film cleanliness are correspondingly high."

Considering the production chain from a cleanliness perspective

Traditional cleaning processes, which are used to achieve the required level of cleanliness at the end of production, reach their limits here. It is therefore necessary to scrutinize every phase of product creation from a cleanliness perspective. This begins as early as the development stage: Is the component designed in such a way that it is easy to clean? Cleanability has a decisive influence on a new product and its added value. In other words, it is an enabler.

Each production step, such as milling, forming, casting, additive manufacturing or coating, must then be assessed in terms of its influence on the technical cleanliness of the overall product. Among other things, this involves determining whether the operating and auxiliary materials used can be easily cleaned or contain critical substances. Or whether residues from the pre-process affect the subsequent processing, making intermediate cleaning necessary. When it comes to assembly and/or final cleaning and packaging, the question arises as to the production environment - is a clean room required? In order to be competitive in the manufacture of components, cleaning must not only be tailored to requirements, but must also be economical and conserve energy and resources.

Efficient and sustainable solutions for all parts cleaning tasks

"The exhibitors at this year's parts2clean are presenting optimally adapted and future-oriented solutions for these requirements," reports Ramtin Randjbar-Moshtaghin. "Regardless of the materials from which the workpieces to be cleaned are made and whether they are deburred, pre-cleaned, intermediate cleaned, final cleaned or high-purity applications." The portfolio includes equipment, systems, media and process technologies for fluid-based processes and energy-efficient drying as well as solutions for dry cleaning. Cleaning containers and workpiece carriers, technologies for water treatment and bath care as well as for the control, monitoring and checking of cleaning, rinsing and drying processes and the cleanliness achieved are further areas. Solutions for the automation of cleaning, including parts handling, as well as for the digitalization and integration of cleaning processes in networked production environments and the use of AI offer opportunities to counteract the shortage of skilled workers. The spectrum is rounded off by cleanrooms and cleanrooms, cleaning services and specialist literature. "Thanks to the complete range and the participation of all relevant suppliers from the various segments, users of industrial cleaning technology from all sectors can obtain comprehensive information about development trends, technologies, methods and processes," adds Ramtin Randjbar-Moshtaghin. "This also includes the optimization of existing processes in terms of achievable cleanliness and their more resource- and energy-efficient design."

Competition-relevant topics and innovations also at the parts2clean supporting program

The supporting program at this year's parts2clean is also optimally adapted to the current challenges in parts and surface cleaning. In the bilingual p2c.EXPERTFORUM, renowned experts from research and science as well as from associations and industry will offer knowledge and know-how as well as benchmark solutions on various topics in simultaneously translated (German <> English) presentations. The special show "Process Chain Technical Cleanliness", organized together with the CEC (Cleaning Excellence Center), looks at cleaning with the surrounding manufacturing processes and thus provides the basis for pragmatic solutions. The German Industrial Parts Cleaning Association (FiT) will once again be represented with a special show area and informative presentations. A crowd-puller on 9 October will be the presentation of the "FiT2clean Award", an innovation prize endowed with 10,000 euros, with which the association annually honors outstanding achievements and innovative solutions in industrial component cleaning (OM-7/25).