DeburringExpo 2023: Surface finishing for medical and pharmaceutical technology

The requirements for surfaces in medical and pharmaceutical technology are very high and continue to increase. DeburringExpo 2023 presents new and further developed products and services for deburring and surface treatment in the medical field.

In hardly any other industry are the demands on the properties and condition of surfaces as high as in medical and pharmaceutical technology. Accordingly, increasingly higher demands are being placed on deburring and surface finishing. For these quality-critical manufacturing steps, DeburringExpo will present new and further developed products and services from October 10 to 12, 2023, at the Karlsruhe Exhibition Center. The range of solutions at the 5th Leading Trade Fair for Deburring Technologies and Precision Surfaces will be rounded off by the integrated, bilingual specialist forum and various theme parks.

In medical technology, work is consistently being done to make products for endoprosthetics, instruments and components for diagnostic and therapeutic devices more patient-friendly, functional and durable by using new materials and manufacturing technologies, such as additive manufacturing. The properties and nature of surfaces play a key role in this. In addition, the European MDR (Medical Device Regulation- Medical Device Regulation) makes it necessary to deal intensively with surface processing as well as the validation and quality management of the corresponding processes. Parts and components such as containers, stirrers, mixers or tabletting punches, which are manufactured for pharmaceutical technology, also have to meet the highest demands on surface quality. They must be highly precise, mirror-smooth and free of defects so that they are easy to clean, cross-contamination by product residues or microorganisms is avoided and wear is minimized. In both industries, therefore, the key is to give products the surface finish that will ensure long-term safe and reliable use. Factors such as traceability, the energy and resource efficiency of the processes, and their integration into interlinked production must also be met.

Surfaces for medical and pharmaceutical products that meet requirements

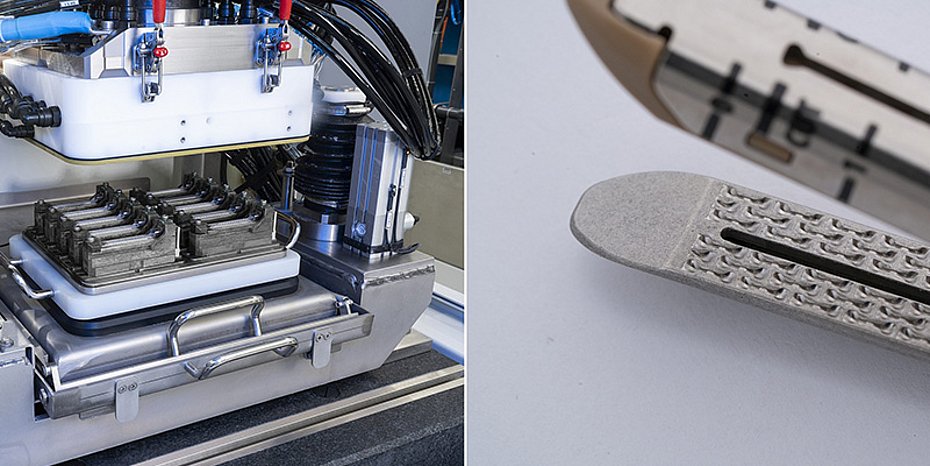

"Thanks to its cross-industry and cross-material exhibition spectrum, DeburringExpo also supports companies from the medical technology and pharmaceutical industries in their search for suitable processes," Hartmut Herdin, Managing Director of the private trade fair organizer fairXperts GmbH & Co. KG, is certain. This is supported by the fact that many of the participating companies have experience in these industries and the entire spectrum of technologies, processes, tools and services for deburring, edge rounding, cleaning and surface finishing will be presented. This includes mechanical deburring with tools, vibratory grinding, brush deburring, blasting with solid and liquid media, among others. For the latter, for example, a new development will be presented for fully automated and production-integrated deburring and simultaneous cleaning. The processing medium is liquid, recycled carbon dioxide, which is compressed inline into fine granules and blasted at supersonic speed onto the surface to be processed.

In addition, the range of exhibits includes various special technologies. For example, ultrasonic deburring allows burrs to be removed from a wide variety of materials in a fully automated, process-reliable manner that can be validated in accordance with regulatory requirements. Abrasive flow machining (AFM) is used for deburring, edge rounding and polishing of complex components. The strengths of the process include the machining of internal areas and surfaces that are difficult to access, for example also in additively manufactured components. The ECM process (electrochemical metal machining) can be used to deburr parts made of almost all metals, such as titanium alloys or hardened materials, and to round their edges in a targeted manner. A further development of the process is PECM (precise electrochemical metal machining). This technology makes it possible to produce three-dimensional shapes, contours and structures with very high precision. An imaging accuracy of < 20 μm and a surface finish of Ra < 0.1 μm can be achieved. Laser deburring scores highly when it comes to removing fine burrs and flakes from the outer contours of very filigree, thin-walled workpieces. The process can even be used to process edges of bores with diameters of a few tenths of a millimeter. In contrast to conventional electrochemical polishing, electrofinishing is performed dry using special polymer particles. Among the advantages of the process is that a very high level of gloss is achieved without micro-scratches, even on geometrically complex as well as additively manufactured components. "The diversity of technologies makes it possible to discuss the strengths and limitations of the various processes, tailored to the respective application, directly on site with experts," adds Hartmut Herdin.

Added value knowledge transfer through the bilingual expert forum

In addition to the exhibitor presentations, the supporting program of DeburringExpo offers a lot of knowledge and know-how. The theme parks "Automated Deburring", "Cleaning after Deburring" and "Quality Assurance in the Deburring Process" provide information on current developments for these tasks. The main focus of the technical forum integrated into DeburringExpo, with simultaneously translated (German <> English) presentations, will be on fundamentals, ways to optimize processes and costs, reports on best-practice applications and trends, and on the special content of the theme parks. Participation is free of charge for visitors to the leading trade show, as is a copy of the updated and expanded brochure "Basiswissen Entgrattechnologie" in German and English. For more information, the complete range of exhibits and the technical forum program, as well as the preliminary exhibitor list, visit www.deburring-expo.de.(OM-07/23)