VersaCut from Nanosystec deburrs precisely with laser radiation

The Versacut precision machine from Nanosystec removes burrs by laser beam in a single manufacturing step. From October 10 to 12, 2023, Nanosystec will show a demonstration setup at the Deburring Expo.

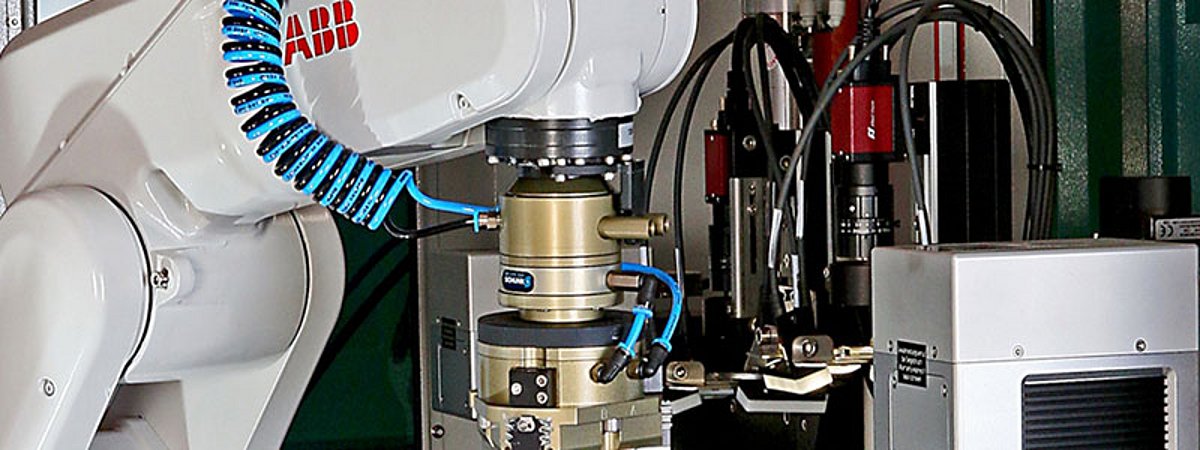

Compared to conventional processes, laser-based material processing also offers many advantages when deburring precision components. In the Versacut precision machine from Nanosystec, a laser beam removes burrs fully automatically in a single production step. With the non-contact process, neither tool wear nor deformation of the workpiece due to mechanical forces occurs. High-resolution image processing and multicolor LED illumination support the automatic processes.

Special algorithms ensure reliable detection of even complex contours with precision in the micrometer range. An XY scanner uses this data to quickly guide the laser beam to the right spot and process any contours. Focal diameter and laser intensity can be ideally adjusted to the task at hand during the process. A variety of laser sources are available, with the system mostly using robust and maintenance-free lasers with a few 10 ns pulse duration and high repetition rates. Nanosystec will be exhibiting at DeburringExpo 2023 at booth 708.