Heinz Berger shows new peripheral grinding machine at GrindTec 2023

The new generation of the RFS/RT/NT peripheral grinding machine from Heinz Berger Maschinenfabrik will be presented for the first time at GrindTec 2023. The grinding machine achieves surface and/or bevel grinding on circular knives, saw blades and circular blanks using the pendulum or plunge-cut method.

Thanks to an additional grinding axis, the new RFS/RT/NT peripheral grinding machine from Heinz Berger can be used for subsequent grinding in a single clamping. For example, the surface of the workpiece can be ground flat and a bevel machined onto the cutting edge in one work cycle. The circular blade is held in the rotating workpiece holder by mechanical clamping devices, permanent magnets or electromagnets. The workpiece fixture is mounted on a rotary table that can be continuously adjusted from -10° to 60° so that a wider range of bevels can be machined onto the circular knife. After each dressing cycle, the travels are automatically compensated and adjusted to the preset peripheral speed.

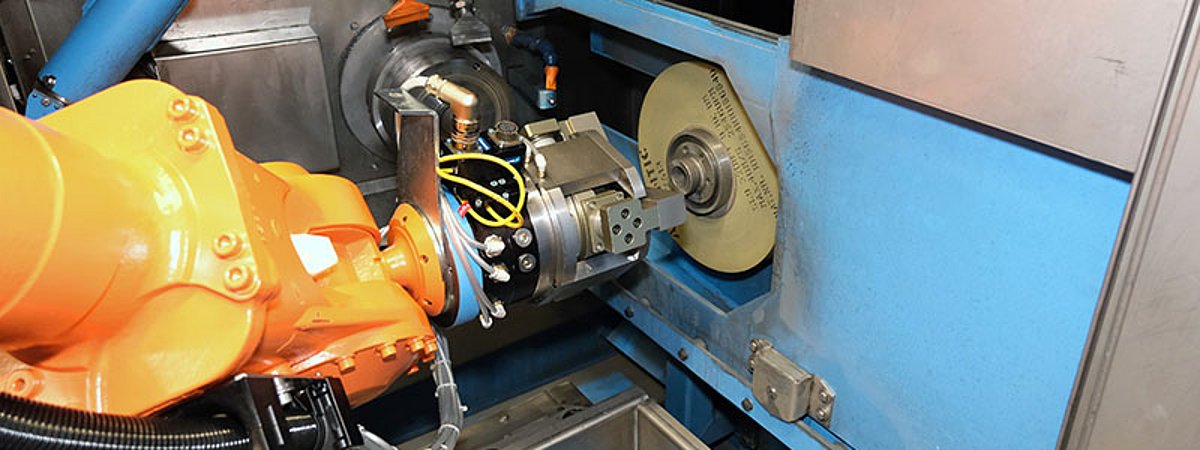

The workpiece and grinding wheel are changed fully automatically by a handling robot. The robot can be equipped with a specially designed dual gripper so that it can pick up both the circular knife and the grinding wheel. Thanks to robot automation, the setup or changeover time is reduced from 30 minutes with manual loading and unloading to 3 minutes. The processing machine can be equipped with sensors and thus becomes a data supplier. This includes operating states as well as status and process information. Measured values are recorded by intelligent sensors and passed on to the machine controller via IO-Link. This communicates with a decentralized higher-level controller. Here, decisions can be made to optimize productivity and the use of resources, as well as an evaluation of the process. Heinz Berger Maschinenfabrik will be exhibiting at GrindTec 2023 in Hall 5, Booth B06.