Hahn + Kolb: Overcoming the shortage of skilled workers with automation

The increasing shortage of skilled workers is presenting manufacturing companies with ever greater challenges. The tooling service provider and system supplier Hahn + Kolb offers a wide range of solutions to optimize existing processes through retrofitting.

Hahn + Kolb's flexible retrofit solutions reduce unproductive downtime in existing manufacturing processes - even for the smallest batch sizes. Even an improved clamping technology system increases profitability through fewer tool changes and shorter run times per workpiece. Multiple clamping on Atorn pyramids or clamping towers reduces unproductive downtimes and enables multiple machine operation by fewer personnel. For this purpose, Hahn + Kolb has developed the Atorn RS-Z centric clamping device specifically as a basis for automation clamping technology and as an all-rounder for single and multiple clamping. In combination with the Atorn zero point clamping system, it allows pallets, fixtures, vices or workpieces to be changed in seconds with a defined zero point - saving 90 percent set-up time and costs of up to 100,000 euros.

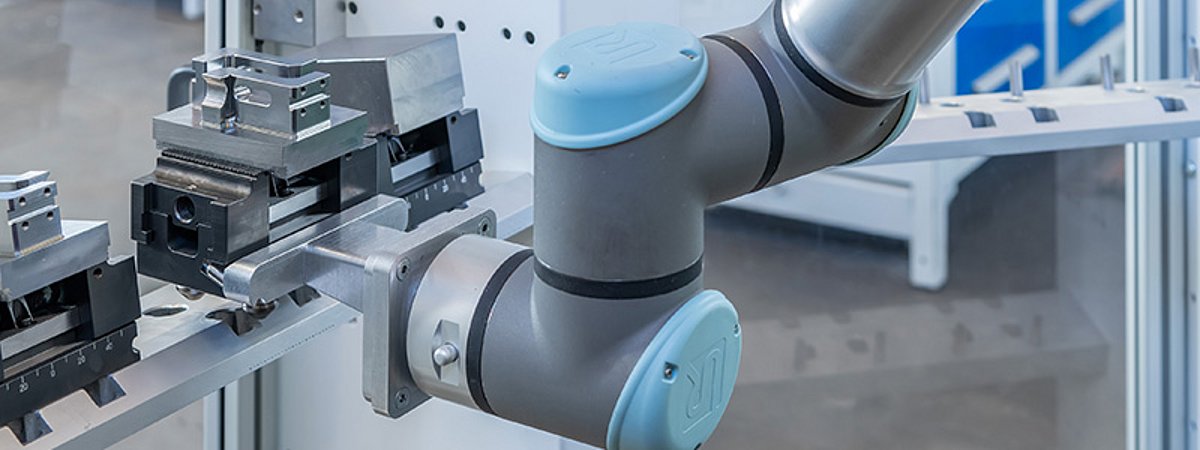

Pneumatically or hydraulically driven gripper systems are also part of the Hahn + Kolb range. They change workpieces from storage to the clamping device of the machine tool - fully automatically and without high investment - and can be a first step into automated handling of workpieces during the machining process. Modular robot cells represent a simple but very effective retrofit solution for existing machines. Thanks to their modular system, they adapt optimally to the given production spectrum and can be configured variably according to customer requirements. If a process cannot be fully automated or requires cooperation with a human, collaborative robots ensure greater efficiency and safety in placement, quality assurance, assembly, incoming goods, and ancillary activities such as polishing or sorting. Completely autonomous production is made possible by machine-independent terminals - where each individual workpiece is automatically guided into the machining area of the machine and back again. Hahn + Kolb supports customers in their entry into automation with complete service from a single source - from individual on-site consultation to installation of the appropriate products and after-sales service.