Hahn + Kolb: Atorn disk brushes for automated finishing

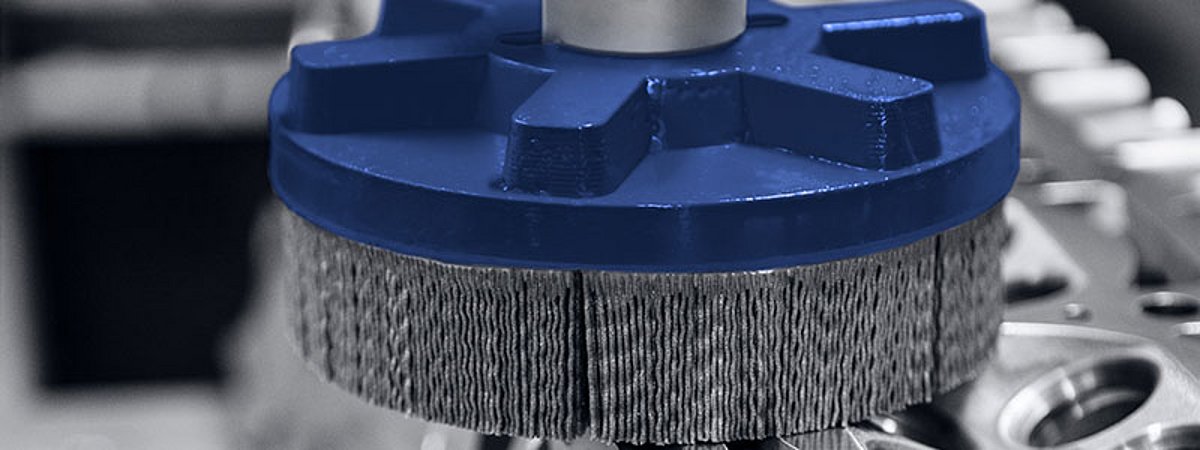

Precise deburring, controlled rounding of edges and high-quality surface finishing: The Atorn disc brushes from Hahn + Kolb are among the high-performance solutions in automated finishing and enable high-quality processing results.

Atorn disk brushes are used downstream of the machining process - without reclamping directly on the machine. They are suitable for milled, turned, ground, sintered or cast components - ideal for high surface quality with maximum process reliability. The high-tech bristles with a high abrasive grain content produce an aggressive, uniform brushing effect - without changing the geometry of the workpiece. Particularly abrasion-resistant and dimensionally stable, they straighten up again and again during the process. This means that the edge rounding and surface finish remain constant - even at high quantities and process speeds. Use with cooling lubricant, water or oil is possible and recommended.

Atorn disk brushes in two versions

For maximum precision, the brushes have a standardized holder for combination milling arbors and cutter heads (DIN 6357 / 6358). They can be used directly in machining centers, CNC machines or robot cells - without any additional clamping accessories. Atorn disc brushes from Hahn + Kolb are available in two versions: with ceramic grit for universal use and with silicon carbide grit, which is particularly suitable for machining aluminum and non-ferrous metals. Both variants are available in different grit sizes and diameters.