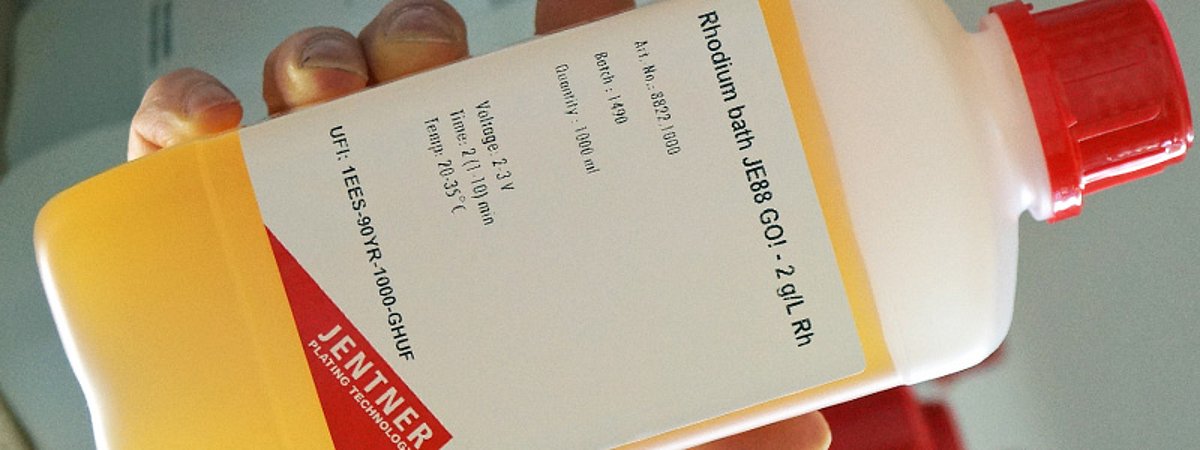

Electroplating electrolyte with recycled rhodium from Jentner Plating Technology

Jentner Plating Technology developed an innovative process for recovering rhodium from used electrolytes: The new product Rhodium Clean for electroplating plants made from recycled rhodium is of the same high quality as a new product.

Sustainability and environmental protection are generally high on the agenda of the JentnerGroup from Pforzheim. This applies not only to the contract electroplating division of C. Jentner GmbH, but also to Jentner Plating Technology GmbH, which specializes in the manufacture and sale of electroplating electrolytes and small electroplating equipment. Their latest product, Rhodium Clean, is an electrolyte containing recycled rhodium from used baths. The process used here was developed in-house. The result is reusable electrolytes of the same quality as new products. "Rhodium is simply indispensable in electroplating, but as the most precious metal of all, it is extremely difficult to obtain. Recycling is not only important in terms of economic efficiency. The environment also benefits decisively, considering the pollution associated with new mining," says Revin Shangula, laboratory manager at JentnerGroup. "In this respect, every gram of rhodium recovered is a complete success in more ways than one."

The intention to recover rhodium using a new process is dated October 2021, which was implemented from scratch by Revin Shangula and has been successfully used in live operations for several months. In this process, the old bath arriving either from the company's own customers or from third-party companies is first analyzed for the content of rhodium and foreign metals, and the individual procedure for the chemical process is then determined. Depending on the results of the analysis, the rhodium content and foreign metals may first be separated or a new electrolyte may be produced directly. In both cases, the rhodium returns to the recyclable material flow free of any base metals. The background to this is that rhodium electrolytes are no longer usable after frequent use with then only poor quality characteristics. This applies, for example, when too many foreign metals are contained, the acid content has increased or the deposition value is no longer sufficient.