Benseler represented in the Czech Republic for 10 years

The Benseler Group has been operating successfully in the Czech Republic with its subsidiary Prove Tech CZ for ten years - the order volume at the Říčany site is growing continuously. A second cleaning line was recently installed in order to be able to process steel and aluminum components separately.

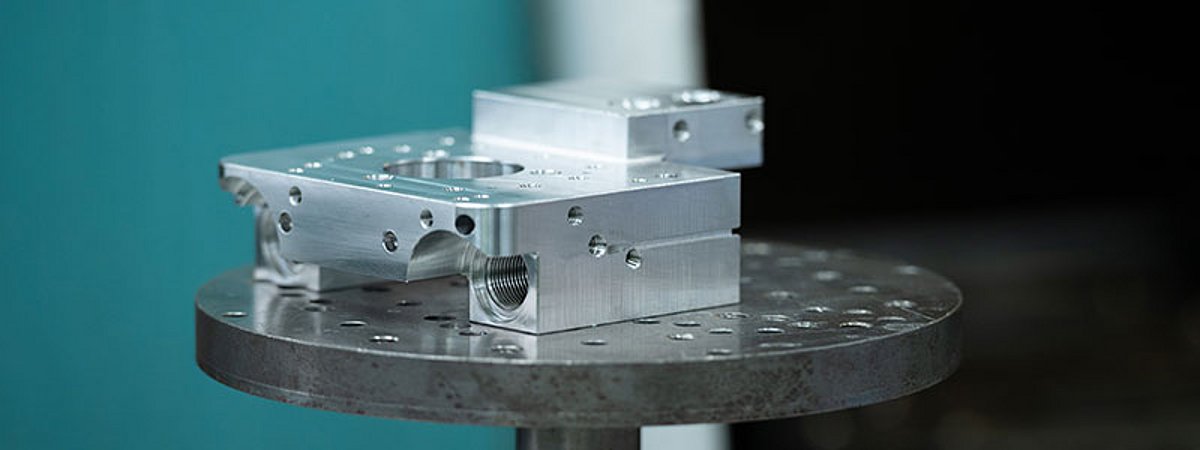

The increasing demand for on-site machining close to the customer as well as high wage and energy costs for customers in Western Europe had already led to Benseler's decision to set up its own site in the Czech Republic in 2015. Components that used to be typically manufactured in Germany are now increasingly being produced in countries in Eastern Central Europe - particularly in mechanical engineering, hydraulic technology, but also in the automotive and furniture industries. At its site in Říčany near Prague, Benseler offers comprehensive services for thermal deburring (TEM), electrochemical metal machining (ECM) and the cleaning of technical components - including the associated fixture production. The figures show that the company is meeting the needs of its customers: "We have more than doubled our turnover here since we started," says Silvio Peschke, Head of the Benseler Deburring business unit. Together with Jiří Prokop, he is the Managing Director of the Benseler subsidiary Prove Tech. "Today, we are one of the few service providers with comprehensive expertise in TEM and ECM in the Czech Republic." Customers include companies such as SKF Lubrication Systems CZ, TENZA, Power Cast Ortmann, TOX, IMI International and Hettich.

Second cleaning line from Benseler in the Czech Republic

With a new second cleaning line at Benseler's Czech site, it is now possible to clean steel and aluminum components completely separately from each other. This prevents the contamination of sensitive light metal parts by iron oxides, for example. The implementation of technical cleanliness requirements is therefore possible at an even higher level. Prove Tech CZ also operates three TEM systems, an ECM line, two cleaning systems, CNC processing units and a hand washing line. Thanks to in-house fixture production, the deburring specialists can react flexibly and quickly to customer-specific requirements.