ArtiMinds Robotics: Robot-assisted deburring, grinding and polishing

At this year's Deburring Expo 2023, ArtiMinds Robotics will show how the grinding, polishing and deburring of components with complex geometries can be automated with robots thanks to intelligent software solutions.

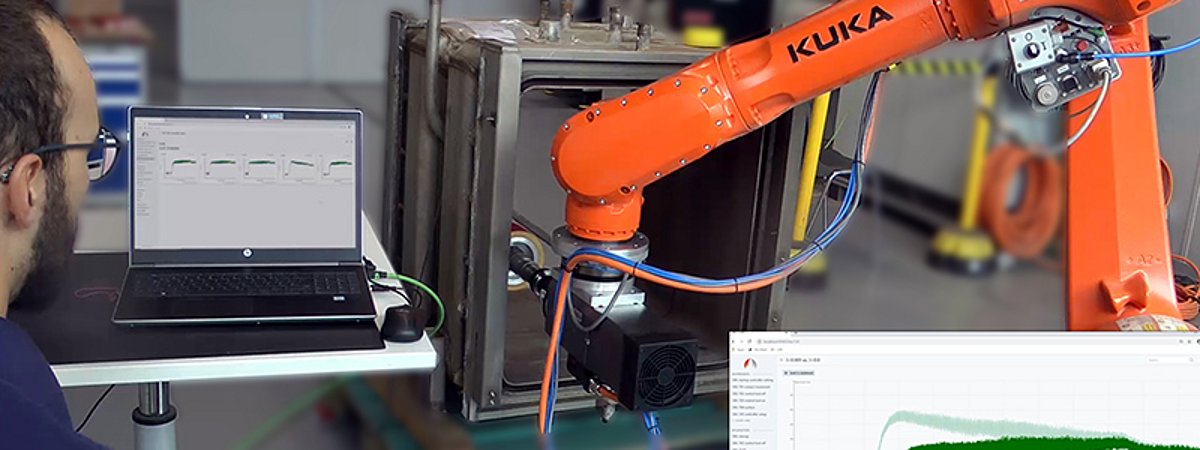

When finishing metal, plastic or composite parts, grinding, polishing and removing burrs is a common work step. Since the components usually have complex geometries, the machining is often still done manually. Intelligent software solutions such as the ArtiMinds Robot Programming Suite (RPS) provide support in the robot automation of such processes with tolerances. For example, it allows CAD models to be imported in order to automatically generate robot paths. The result is accelerated programming and more precise path planning.

Another challenge in surface processing is component and process tolerances. To ensure that the exact amount of material is actually removed at all times, the robot must be able to dynamically adjust and regulate its movement depending on the process forces that occur. ArtiMinds RPS facilitates the integration of the necessary sensors and the programming of the force-controlled sub-processes by means of already integrated interfaces and corresponding function blocks. In order to optimally adjust process parameters, robot movements, sensor data and error codes can be automatically monitored and visualized with the analysis software Learning & Analytics for Robots (LAR). ArtiMinds Robotics will be exhibiting at DeburringExpo 2023, booth 412.