Dürr adhesive products used outside the automotive industry for the first time

Dürr's adhesive products will in future be used by sister company Homag Plattenaufteiltechnik GmbH to build the vacuum tables for Sawteq saws. This is the first time that Dürr adhesive products have been used outside the automotive industry.

The use of Dürr adhesive products is a new approach both for Homag as experts in the woodworking industry and for the machine and plant manufacturer Dürr. Until now, Dürr dispensing technology for adhesives has only been used in the automotive industry. Now the company has further developed its products and processes so that the company's adhesive applications can also be used in other branches of industry. The machinery and plant manufacturer Dürr has many years of experience in the field of car body construction, final assembly and battery bonding. Joining components using dispensing technology for different applications is particularly challenging in general industry. Thanks to a modular product system with standardized operating software, the machine and system manufacturer offers bonding technology at the highest level. "We are delighted that we were able to win Homag Plattenaufteiltechnik GmbH as a reference project," explains Fabian Schilt, head of the European industrial sales team at Dürr. "Thanks to synergies within the Dürr Group, we were able to make application products from the automotive industry available to the wood industry."

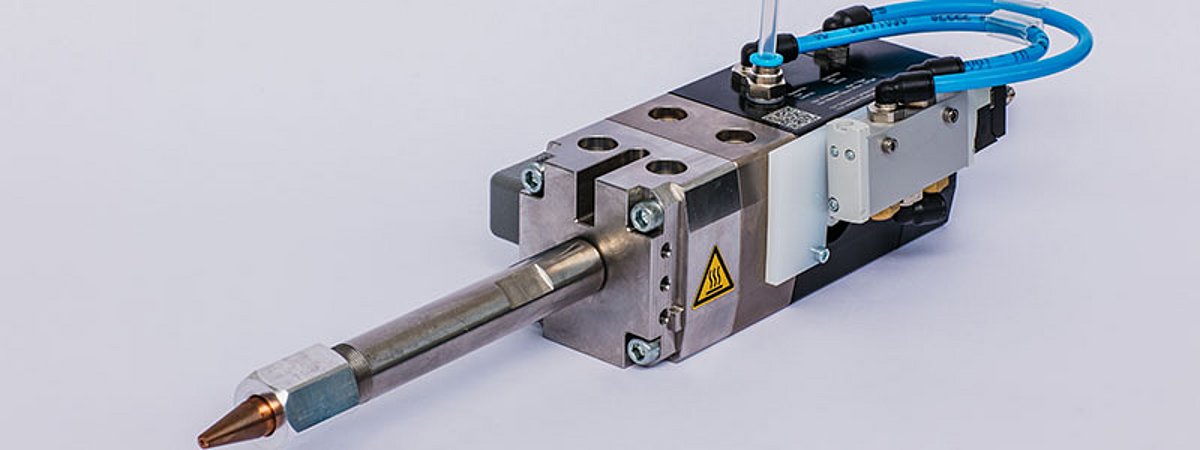

With the horizontal panel dividing saws, Homag provides its customers in both trade and industry with precise, economical and flexible panel cutting. The air cushion tables enable easy and safe handling of the parts during processing. Previously, the table tops were screwed onto the sheet metal housing by hand and additionally sealed with silicone. "In order to achieve better repeat accuracy and higher application quality, for example with the right surface flatness, we decided to automate the process with Dürr products," explains Dennis König, project manager from the Industrial Engineer department at Homag. The EcoRam barrel press for material supply, the EcoShot Meter as a dosing unit and the EcoGun2 PVA04 as an applicator are currently being installed for this purpose. Everything is controlled via the new EcoHVMP4 pump and system controller. Commissioning of the automation solution is planned for early 2025. Dürr is also installing its new EcoHVC4 operating software for the first time in the Homag project. Previously, the system control was purely project-oriented, with the software being adapted for each system on a project-specific basis. With the HVMP4 standard, the focus is now on the individual components, which can be combined with each other via standardized interfaces. Customers can select different Dürr bonding products according to their wishes and requirements and the system enables easy integration of the parts. The individual products are fully tested and guarantee a smooth process flow.