Dreyplas additive improves paint and varnish surfaces

The fine powder Mipelon from Dreyplas significantly improves the sliding properties, abrasion resistance and chemical resistance of paints and coatings. Mipelon is an environmentally friendly alternative to PTFE, which is affected by the PFAS debate.

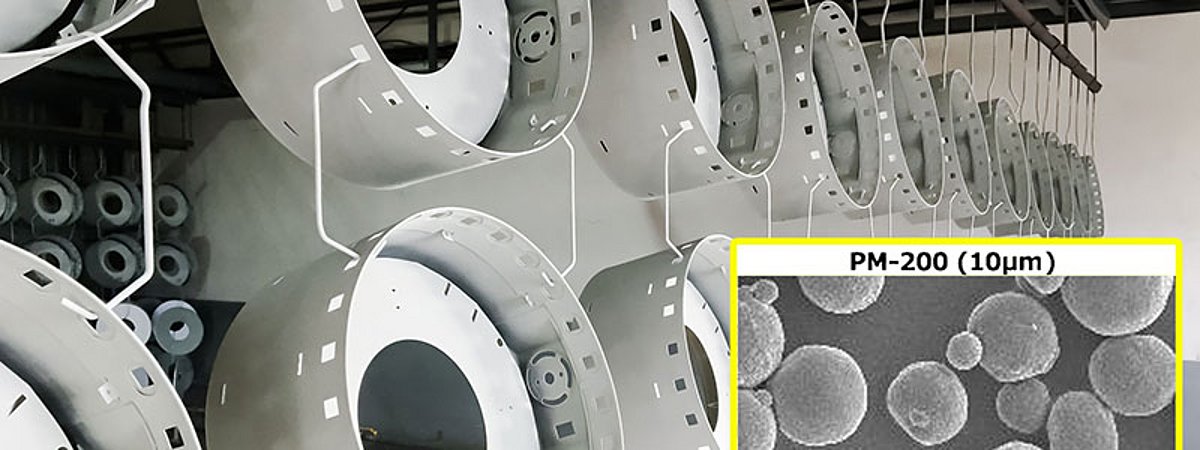

Mipelon is a fine powder whose spherical particles consist of ultra-high molecular weight polyethylene (UHMW-PE). As an additive, it significantly improves the slip properties, abrasion resistance and chemical resistance of paints and coatings. Typical applications include electrostatic powder coating, water and solvent-based spray coating and dip coating. Mipelon thus offers a high-performance, environmentally friendly alternative to PTFE, which is affected by the PFAS debate. Dreyplas will present its application properties and possibilities at the European Coating Show 2025 (ECS), which takes place from 25 to 27 March in Nuremberg, Germany, at booth 4A-527. Dreyplas, as the distributor for Mitsui Chemicals in Europe, sells and develops the product together with customers for solutions to optimize tribological properties with UHMW-PE instead of PTFE.

Mipelon additive improves tribological surface properties

Mipelon is characterized by its high chemical resistance to acids, alkalis and organic chemicals. In addition, it absorbs practically no water or moisture. Most Mipelon grades are suitable for food contact applications in accordance with EU and US legislation. Unlike PE powder, which is also used for this purpose, Mipelon does not tend to swell even at high temperatures and retains its shape and function. Compared to PTFE, it enables a lower coefficient of sliding friction and better abrasion resistance at the same or reduced dosage, which makes it economical to use. The lower melting temperature of around 135 °C can have a limiting effect when substituting PTFE. The molecular weight of Mipelon is up to 2 million g/mol. The average size (D50) of the spherical particles is only 10 µm for the PM-200 type, which is currently the smallest size in this product group worldwide. For type XM-220 the D50 value is 30 µm and for XM-330 65 µm. The finer powder grades are mainly used in the paint and coatings industry. New types, including LM-200 with a D50 value of less than 5 µm and around 6 µm, are currently under development. The latter is already available for sample purposes. Commercial availability is planned for the end of 2025.