New plasma printing technology from INP receives DATIpilot funding

A new plasma printing technology developed by the Leibniz Institute for Plasma Science and Technology (INP) enables the precise modification of surfaces on an extremely small scale. The Federal Ministry of Education and Research has now provided funding for this.

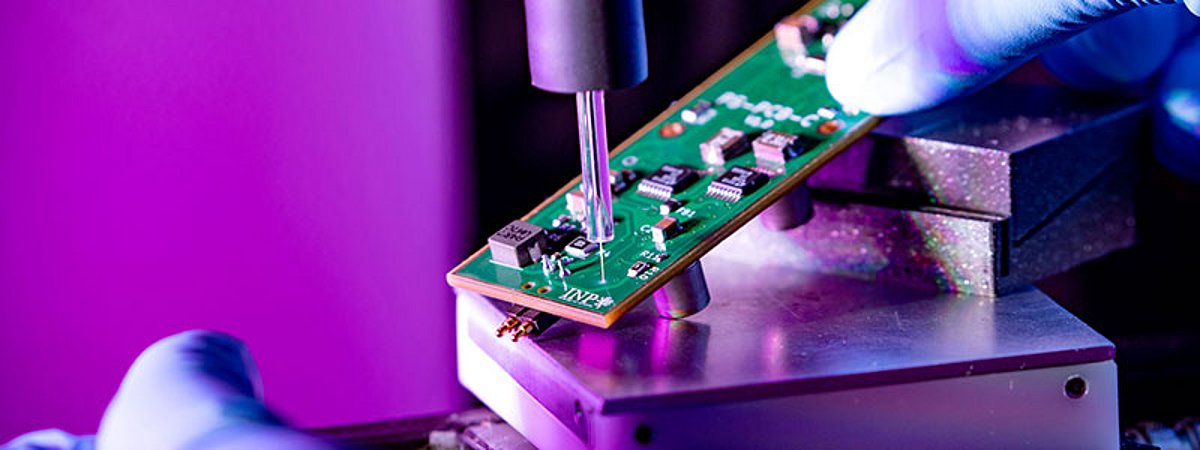

INP researcher Dr. Laura Barillas-Mora has received an Innovation Sprint grant from the DATIpilot program of the German Federal Ministry of Education and Research (BMBF) for the further development of the plasma source used in the system. The new plasma printing process enables the coating of materials such as metal, polymers, fibers and paper with wafer-thin layers with a structure size of just 40 micrometers, which is roughly the thickness of a human hair. The properties of these layers can be precisely adapted, for example in terms of their thickness or chemical composition. In addition, the new plasma printing process enables surface activation, functionalization, chemical structuring, fine cleaning and the removal of layers. This opens up a wide range of potential applications, including in medical technology, biochips, electronics, materials development, optics, photonics and microelectromechanical systems (MEMS). The technology developed at INP offers numerous advantages. The direct application of layers without the use of masks or templates saves time and simplifies production processes. This is particularly important in areas such as microfabrication, life sciences and printed electronics. The technology is also more environmentally friendly, as it consumes significantly less energy and material compared to conventional methods.

"Our plasma printing technology makes it possible to precisely process surfaces without masks. This allows companies to optimize their production processes and work in a more environmentally friendly way at the same time," explains Dr. Laura Barillas-Mora, researcher at INP. "With the support of the DATIpilot program, we have the opportunity to further develop the core component of our technology - the micro-atmospheric pressure plasma source, which has already been successfully tested in the laboratory - and turn it into an industrial prototype." The project funded at the INP is called "Micro-APPS: Development and transfer of a micro-atmospheric pressure plasma source". The BMBF is providing funding called "Innovation Sprint" as part of the DATIpilot program. With a budget of 150,000 euros and a duration of 18 months, the first industrial prototype can now be produced at the INP. Further tests and validation of the plasma source are also planned. Laura Barillas-Mora, project manager at the INP, explains: "Our focus is now on developing an industry-compatible design, particularly in the areas of user interface, electronic control and the necessary certifications. We are also looking for partners from industry to test and use our plasma source and plasma printing system in industrial environments." To commercialize the technology, Laura Barillas-Mora is planning a spin-off from the INP. Under the name MicroQuasar Technologies, the plasma printing process will enable more environmentally friendly production processes in a variety of areas in the future and the plasma source will be made usable for other applications beyond surface treatment.