Innovent: Antimicrobial coating for contact surfaces

Antimicrobial surfaces are an important means of preventing infection. A research project has succeeded in developing a durable cold plasma-sprayed coating for contact and contamination surfaces in public areas.

Contaminated surfaces play a key role in the transmission and spread of microorganisms. Antimicrobial surfaces are therefore an important means of preventing infection. The coronavirus pandemic in particular has raised public awareness of this issue. The Safe TOUCH research project funded by the IGF has succeeded in developing a durable metallic/ceramic coating made of Al2O3 with permanent antimicrobial properties (by adding a small amount of Cu). The cold plasma-sprayed coating is just a few µm thick and can be deposited on all rough surfaces such as metals and temperature-stable plastics in various designs. The new coatings are adhesive and abrasion-resistant (comparable to hard anodizing!). The Cu particles improve the adhesion and abrasion properties of the Al2O3 coating.

Proven antibacterial and antiviral surface effect

Their antibacterial effect has been successfully tested against E.coli (gram-) and S.aureus (gram+), as well as their antiviral effect using the example of the modified vaccinia virus strain Ankara (MVA) and the murine norovirus (MNV). For this purpose, tests were carried out in accordance with ISO 22196 and ISO 21702, in which the surfaces to be tested were brought into contact with a defined quantity of bacteria or viruses. In the tests designed for contact times of 24 hours, a very good effect was demonstrated after just 60 minutes. The effect also remains stable in the long term after tests for mechanical stress (washability) and chemical leaching of the surfaces (eluate test). This technology extends the range of available surface solutions in the fight against harmful viruses and bacteria. By applying permanently effective coatings, cleaning processes can be made more efficient and the use of chemical disinfectants can be reduced.

Cold plasma spraying - innovative technology for coating application

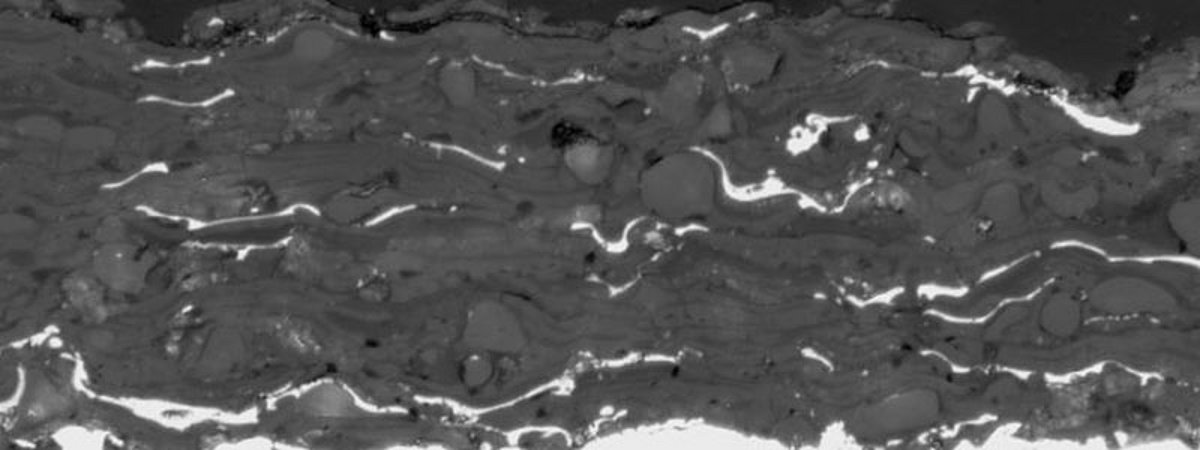

Plasma spraying is a special coating technology in which particles or wire material are melted in a plasma and deposited on the surface as a mechanically stable layer. Cold plasma spraying is a special form of this process. Due to the lower plasma power and process temperature, thermally unstable substrate materials such as plastics can also be coated, depending on the process control. The powders used generally have average grain diameters of approx. 10 - 20µm, which makes the deposition of coatings with a thickness of between 20 and 100µm economical.

Objective of the project

The coatings have been developed in cooperation with the research association Dechema Gesellschaft für Chemische Technik und Biotechnologie e.V.. The aim was to develop a novel, antibacterial and antiviral, long-term active coating for everyday objects that are regularly touched by hands in their function. This should reduce the risk of transmission of germs, bacteria and viruses through touch or physical contact. Preferred areas of application are all areas of public life such as public buildings, event rooms, doctors' surgeries (handles and door handles, handrails, switches, terminals, furniture surfaces), means of transport (handrails, buttons, seats, handles), sales facilities, restaurants (handles, tables and chairs, sanitary areas), companies, institutes, workplaces, workstations, keyboards or telephones. The coating can also be used in high-risk hygiene areas in particular, including places that are difficult to access and problematic for cleaning routines. Equipping wire meshes and filter ceramics with the coating minimizes biofilm formation, which leads to improved usage properties and a longer service life.