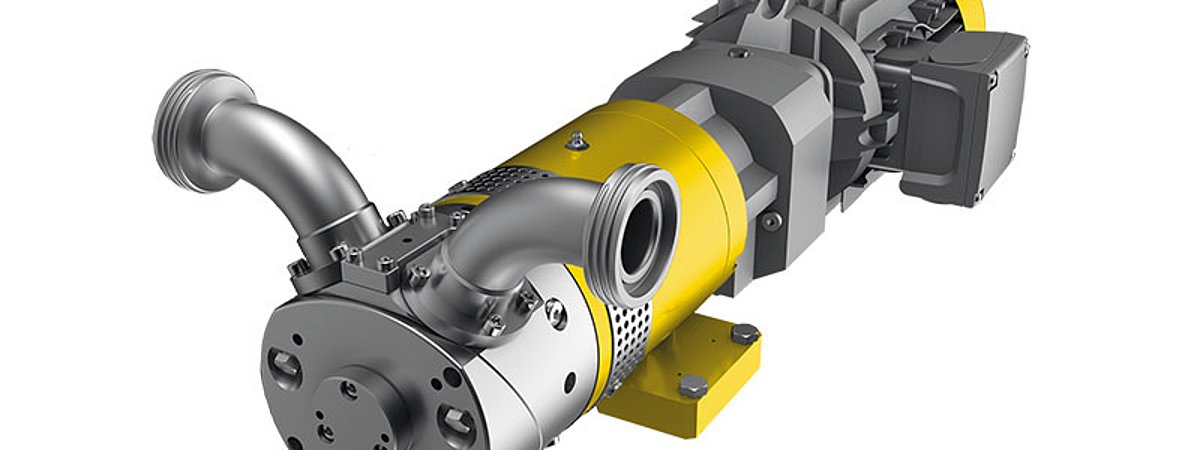

Lutz: New swash ring pump for highly viscous liquids

Lutz Pumpen presents a new wobble ring pump for the gentle transport of up to 30,000 liters of highly viscous liquids per hour such as paints, sealants or greases.

The TR series wobble ring pumps from Lutz use a tried and tested principle: a spherical pump housing accommodates a wobble ring that sits at an angle on a shaft. The rotation of the shaft causes the ring to perform a characteristic tumbling movement. It continuously changes the volume of two chambers on both sides of the shaft. This creates alternating positive and negative pressure, which draws liquids into the pump and expels them through an outlet opening. An efficient principle that has proven its worth with highly viscous liquids - such as oils, greases, paints, sealants and silicones. "The new TR series wobble ring pumps from Lutz Pumpen offer a powerful solution for industrial applications where high flow rates at high viscosity pose a challenge," says Heinz Lutz, Managing Director at Lutz Holding. "The new industrial pumps pump up to 30,000 liters of viscous or thick liquids as well as media containing solids with a viscosity of up to 1,000,000 millipascal seconds and a temperature of up to 205 °C." The new swash ring pumps, which are made of robust stainless steel, are suitable for the paint and coatings industry, the sealants and adhesives industry, the pharmaceutical industry, the cosmetics industry, the oil industry and the food industry, among others.

The new TR series swash ring pumps are characterized by their gentle handling of sensitive products. "Many industrial companies have found that even expensive systems have a negative impact on the quality and integrity of the media during the pumping process when handling high flow rates and high viscosity," says Lutz. This is why there was a particular focus on gentle product handling during the design of the pumps. "Thanks to a special design, the wobble ring pumps generate a continuous and almost pulsation-free flow that is only subject to minimal shear forces. There is no crushing whatsoever. In addition, thanks to the compact design, the contact time of the medium with the pump is reduced to a minimum. This ensures that the quality and integrity of the pumped media are maintained." Proof of this was provided by a company that produces shampoos with integrated air bubbles, among others. With conventional pump systems with high shear forces, the tiny bubbles would have combined to form larger air bubbles during the pumping process. "With pumps from the new TR series, on the other hand, the original product properties are retained." The TR series not only impresses with its high performance and gentle product handling, but also offers effortless integration into existing process landscapes. The TR series wobble ring pumps are available in three configuration levels: The TR015, an entry-level version, operates with a 3 kW motor, 10 bar delivery pressure and achieves a delivery rate of 6000 liters per hour. The TR030 has a 5.5 kW motor and works with a flow rate of up to 12,000 liters per hour at a pressure of 15 bar. Finally, the Goliath of the series, the TR080, achieves an output of up to 30,000 liters per hour with a 7.5 kW motor at a pressure of 15 bar.