Kaeser at Ligna 2023: Reliable and efficient compressed air supply

At Ligna, Kaeser Kompressoren will be showcasing its modern compressor range and, in particular, the space-saving i.Comp 8 and i.Comp 9 Tower compact stations and the Sigma Air Manager 4.0 (SAM4.0) compressed air management system in Hall 15, Stand D13.

At Ligna 2023, Kaeser Kompressoren will be presenting cost-effective, reliable and efficient compressed air supply systems of various sizes. The space-saving i.Comp 8 and i.Comp 9 Tower compact stations - a compressed air supply concept specially developed for workshops - are robust, powerful, compact, easy to maintain, efficient and much more. The heart of the i.Comp family is the innovative drive concept, which combines a number of advantages. For example, it delivers the power as needed to meet the required compressed air demand in a stepless manner. The reciprocating compressor itself is, of course, of the usual industrial Kaeser quality, Made in Germany. It goes without saying that the piston compressors of the i.Comp family are capable of continuous operation. Special solutions ensure an outstanding filling ratio and thus maximum efficiency. With a volume flow of up to 580 l/min, the i.Comp Tower T can be used for many applications in trade and industry and ensure a constant pressure of up to 11 bar with absolute operational reliability.

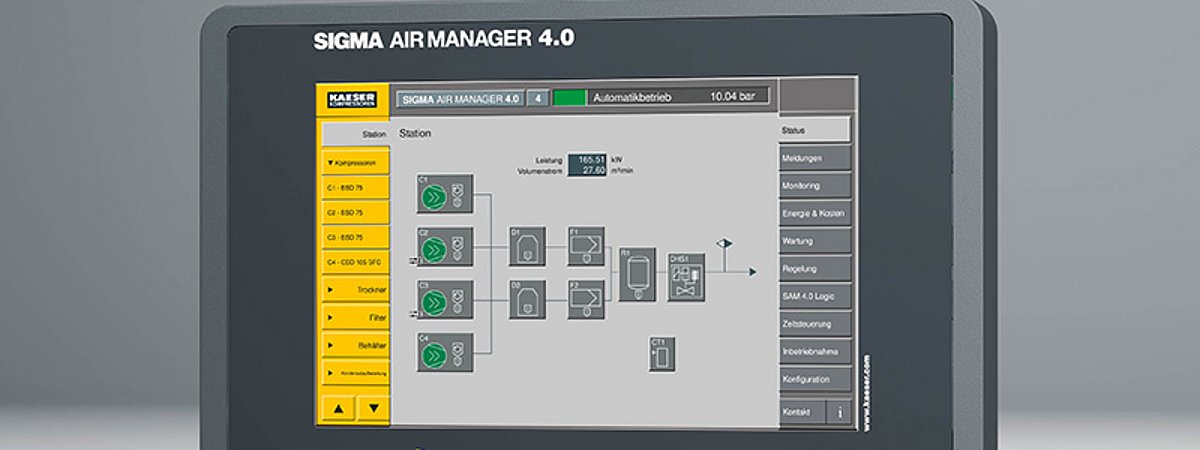

The most important component for making one's own compressed air supply not only highly efficient but also fit for Industry 4.0 is the Sigma Air Manager 4.0 (SAM4.0). The compressed air management system not only perfectly coordinates all components of a compressed air system, but also ensures maximum availability and energy efficiency of the compressed air station at all times thanks to its advanced 3D-Advanced control. In addition, it is also the hub and the basic prerequisite for enabling services in the sense of Industry 4.0 in the first place. These include, for example, permanent energy management or services such as predictive maintenance.