Flux develops pump set for aggressive and toxic media

In cooperation with a leading manufacturer of safety IBCs, pump manufacturer Flux has developed the Safetec pump set, which effortlessly and absolutely safely empties the Variobox FC safety IBC. This allows aggressive chemicals such as sulphuric acid, hydrofluoric acid or formic acid or toxic media to be handled safely.

Drums and intermediate bulk containers (IBCs) are usually emptied using drum pumps. However, this poses the risk of an employee picking up parts that are contaminated with chemicals, for example because they have to open caps or closures. Safety IBCs, on the other hand, are completely closed and sealed. This means that neither the contents can be contaminated with dirt and foreign substances, nor can people come into contact with the hazardous liquids. Flux has entered into a partnership with the leading manufacturer of these safety IBCs, which are becoming increasingly common in the logistics of hazardous chemicals. Together they developed the Safetec pump set, which empties the Variobox FC safety IBC effortlessly and completely safely. The Variobox FC is a double-walled container that does not contain a bottom outlet and can only be emptied using the suction method. The Variobox FC is used in combination with Safetec from Flux whenever hazardous chemicals are to be stored on a site or in a company without a WHG tank. The Variobox and Safetec duo can handle a very wide range of applications and media, such as biocides, formic acid, ammonia up to 20%, iron(III) chloride, acetic acid, ethylene glycol, hydrofluoric acid up to 60%, potassium hydroxide, potassium silicate solution, sodium chlorite, sodium hydroxide, sodium hypochlorite, sodium silicate solution, peroxyacetic acid up to 15%, phosphoric acid, polyaluminum chloride, nitric acid up to 62%, hydrochloric acid, sulphuric acid up to 98%, hydrogen peroxide up to 62%, citric acid and much more.

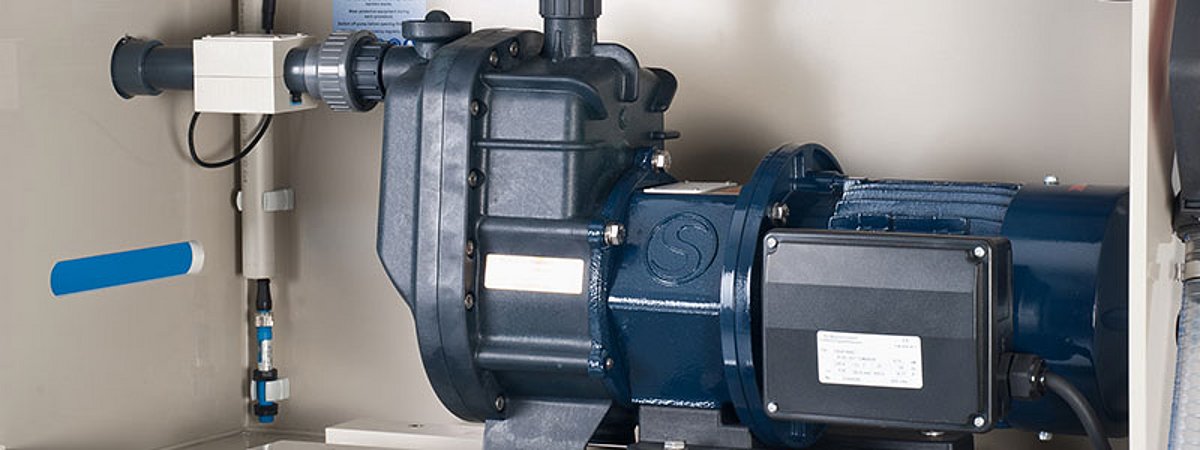

With the Safetec pump set, Flux offers a self-priming system with a quick-release coupling - guaranteeing that contact with the medium is ruled out. The Variobox can therefore only be emptied safely via a permanently installed dip tube. The most important part of the set is the Magson self-priming magnetic centrifugal pump from Flux. The pump chamber and the drive are hermetically separated from each other by a containment shell. This prevents leaks. The pump is also maintenance-free. It is made from the main materials PP or optionally ETFE. It has very good priming characteristics, delivers pulsation-free and quietly. If this is not safe enough, an optional sensor can be purchased to monitor the leakage tray. If, despite everything, medium escapes, e.g. at a screw connection, the pump switches off reliably and the display shows the operator the fault. All components of the pump set, such as the pump, flow meter, sensors and control unit, are combined in a compact console. Safetec is available in different equipment variants and can therefore be tailored to your application. A wide range of options are available, such as an additional touch panel or integrated volume measurement with dosing electronics, as well as automatic operation for filling. Safetec is supplied with a wall bracket, but can also be mounted on a trolley.