Compair introduces AI-based compressed air management system

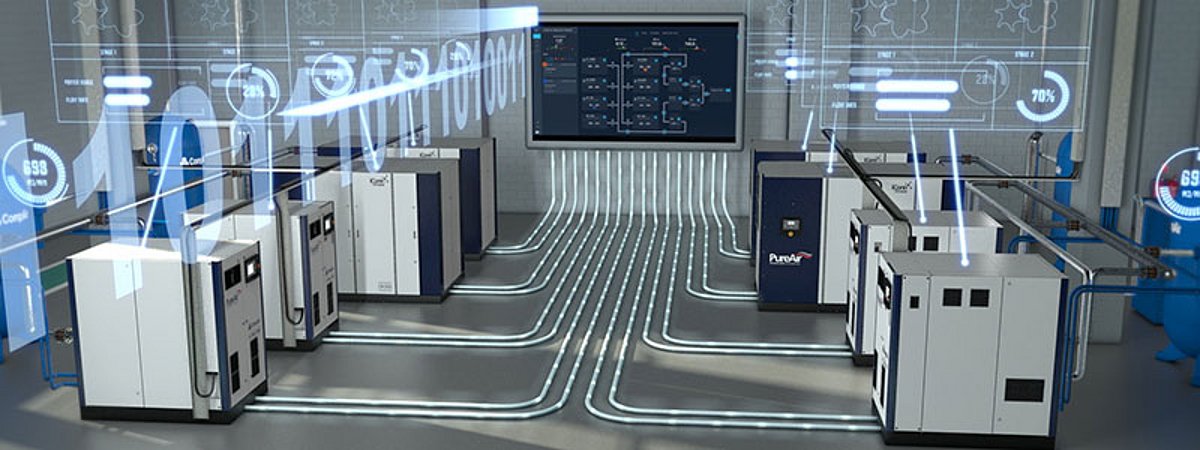

Compair has introduced Ecoplant, an AI-based compressor management system. It is a dynamic solution for managing compressed air systems that adjusts compressor settings in real time and can therefore reduce energy and CO costs by up to 30 percent.

The production of compressed air is extremely energy-intensive. Many conventional control systems are not designed to adapt to fluctuating compressed air demand in real time. As a result, up to 50 percent of the compressed air produced can be lost due to inefficient use, artificial demand and failure to detect pressure losses or leaks. Compair's Ecoplant intelligent compressor management system works differently. The system uses dynamic, AI-based control instead of static control, monitoring key performance indicators across the network and adjusting compressor setpoints accordingly. At the same time, the optimum operating mode is selected. Ecoplant also makes it easy to identify leaks, which can then be isolated. Condition analysis can predict potential problems and provide timely warnings to avoid costly downtime.

Cloud-based remote compressed air system monitoring

The cloud-based management solution combines intuitive predictive maintenance - provided by algorithms - with proactive SAAS analytics and controls. This enables operators to monitor issues remotely from anywhere in the world. Immediate maintenance alerts and user-friendly one-click monitoring reduce response times, avoid downtime and sustainably increase production efficiency. By dynamically monitoring the compressed air system, operators can make more informed decisions based on improved data. Ecoplant can also be customized to the specific requirements of each site, for example to monitor energy consumption and operation. Unlimited historical data is also available. This allows trends such as periods of inactivity or lower demand to be tracked for the entire system or individual processes or compressors. Simple time comparisons can be made within seconds - ideal for identifying inefficiencies and taking appropriate action.

Intelligent compressor management system reduces costs

Andrea Milia, Business Development Manager at Compair, comments on the product launch: "More than 70 percent of all production facilities use compressed air systems, which typically account for between 10 and 30 percent of a site's annual electricity costs. Combined with the energy efficiency of the equipment, high maintenance costs and poor air quality, the generation of compressed air can be very costly. With its dynamic, machine learning-driven control, Ecoplant offers a new approach that allows operators to monitor and manage their compressed air system remotely - reducing maintenance costs and avoiding plant downtime." An online annual value calculator is available on the company's website to help operators calculate the potential savings from using Ecoplant.