Fraunhofer IPT at the Laser World of Photonics: Industrial optics manufacturing

The Fraunhofer IPT will be showcasing technologies for industrial optics production at the Laser World of Photonics 2025 trade fair in Munich. One focus will be on the structuring of optical and functional surfaces.

Whether micro-optics for semiconductor technology, components with functionalized surfaces or high-precision optics for medical technology - the demands on optical components are increasing. Complex geometries, precisely defined surfaces and reliable quality assurance are required. At Laser World of Photonics 2025 in Munich (June 24 to 27), the Fraunhofer IPT will be demonstrating how these requirements can be met consistently and in an industrially suitable manner at its stand in Hall B1, Stand 231. The trade fair presentation will focus on three closely interlinked fields of technology: Shaping, structuring and testing. One major challenge is the cost-effective and rapid production of high-precision optics. At the trade fair, the Fraunhofer IPT will be presenting micro-optical components and lens arrays manufactured from glass using replicative forming. In recent years, the institute has developed the process to such an extent that highly complex geometries with tight tolerances can now be efficiently manufactured in series. New simulation tools and process automation play a key role here. The necessary tools are also created at the institute: through ultra-precision machining with sub-micrometer accuracy. This opens up new options, particularly for sectors such as semiconductor technology, lasers, medical technology or security and monitoring tasks - for example, for components that could previously only be manufactured using expensive machining processes.

Structuring optical and functional surfaces

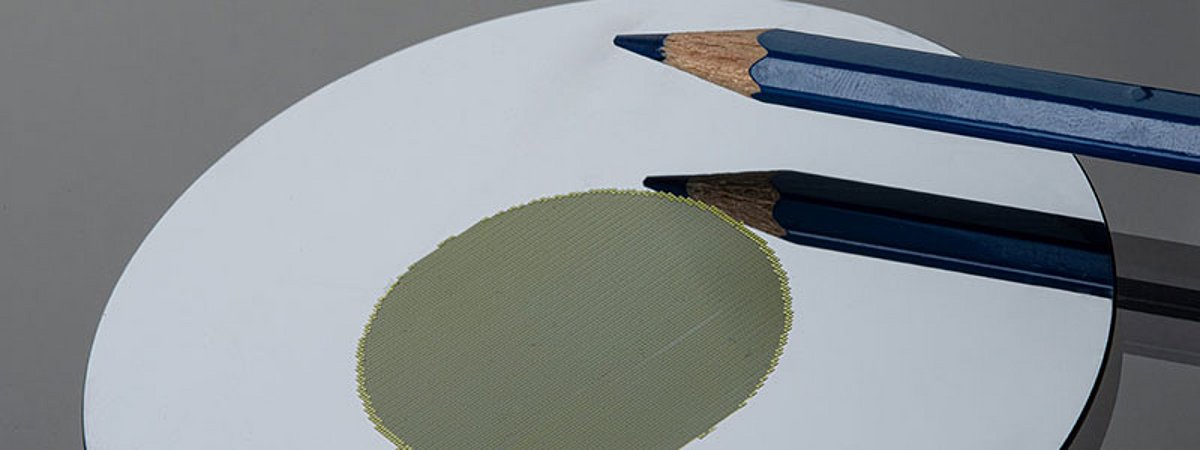

A second focus is on the structuring of optical and functional surfaces. An end-to-end process chain for micro- and nanostructures will be demonstrated, which can be efficiently transferred to large surfaces thanks to a modular process architecture. Smaller structured units are combined to form a continuous, seamless replication tool. This reduces process time, increases reproducibility and lowers costs. The process developed at the Fraunhofer IPT is suitable for optical surfaces, sensor technology or functional coatings, where structural quality and surface area were previously difficult to reconcile. In addition, the Fraunhofer IPT will be presenting a system for the non-destructive testing of miniaturized optical components that was developed at the institute: The exhibited system for optical coherence tomography (OCT for short) provides a live insight into the shape, geometry and internal structures of glass components at the trade fair stand - contact-free and precise.