Peters introduces new Elpepcb PP 2794 filling paste for printed circuit boards

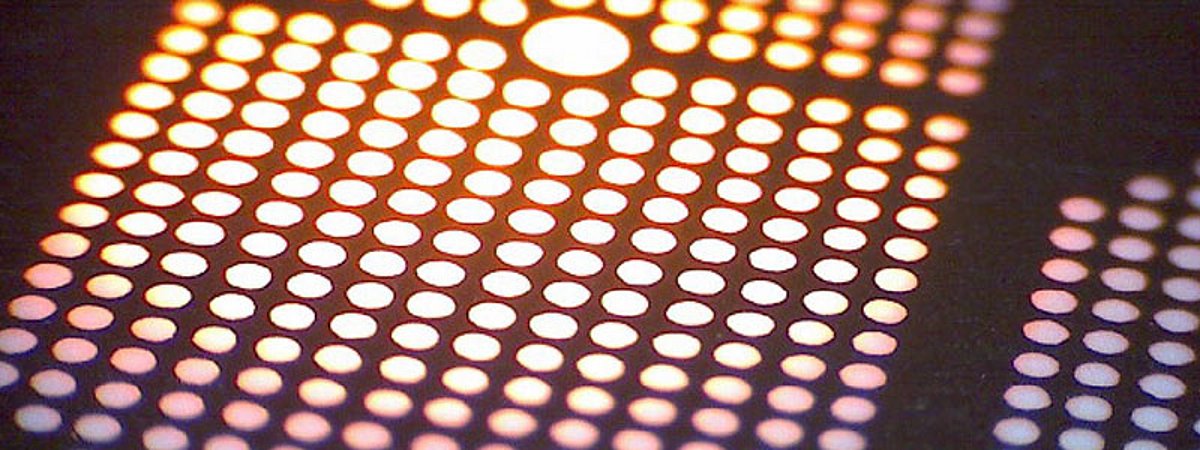

Peters Lackwerke presents Elpepcb PP 2794, a new PCB filling paste for filling holes. The thermally curing via filler enables bubble-free and even hole filling and the subsequent application of planar insulation layers or metallization, especially in the vacuum plugging process.

The new product Elpepcb PP 2794 from Peters will be presented at Productronica 2023. At the trade fair for the electronics manufacturing industry from November 14 to 17 in Munich, booth B3-343, the paint manufacturer from the Lower Rhine region will present the filling paste, which was developed in its in-house R&D laboratory. "The paste shows excellent metallizability and no cracking or delamination," says R&D boss Detlev Schucht, describing the benefits of the paste. The Peters product improves the reliability of the printed circuit board. The solvent-free, 1-component system with a long processing time is available in cartridges as well as large-container packs and makes application easy and economical, according to Detlev Schucht. The adjusted flowability enables the filling of "thick" printed circuit boards with a higher aspect ratio.

Special attention in the development of this paste was paid to achieving the highest possible glass transition temperature (Tg) combined with low coefficients of thermal expansion (CTE). Thus, thermomechanical analysis (TMA) in tensile mode yields a Tg of 158°C and CTE of 25/106 ppm (α1/α2). In Expansion mode, the result is a Tg of 151°C and CTE of 23/72 ppm (α1/α2). "With ELPEPCB® 2794, a modern and high-performance via filler 'Made in Germany' is offered that is readily available worldwide and complies with RoHS requirements," reports Sven Kramer, head of application technology at Peters. In this way, Peters also complies with the sustainability principle. "With our new plugging paste, the customer can be sure that the proportion of hazardous substances that are harmful to the environment and sometimes difficult to dispose of is limited to the maximum permitted limit," says paint engineer Sven Kramer.