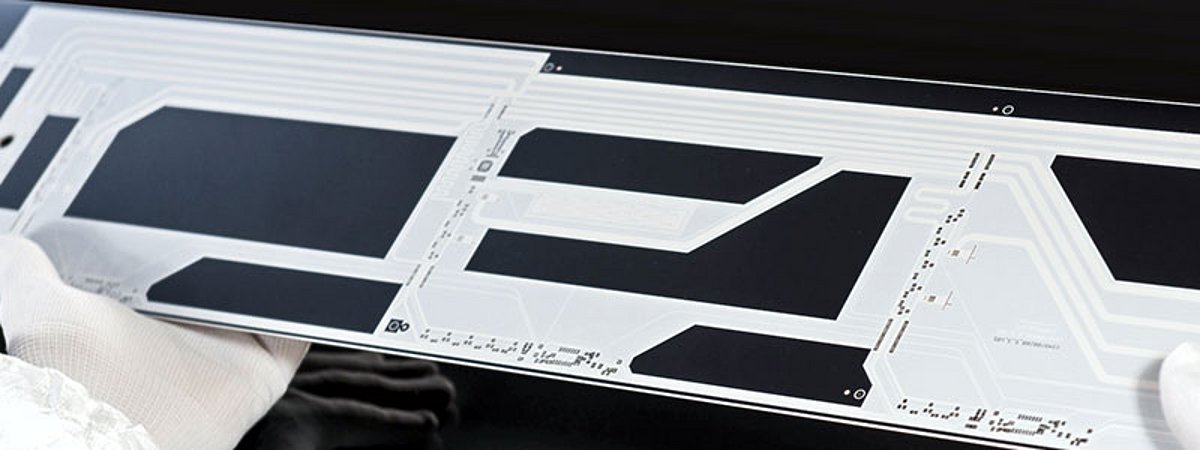

Irlbacher prints glass surfaces for glass circuit boards

Irlbacher, a specialist in the processing and functionalization of glass, has developed a new process for manufacturing, printing and equipping glass PCBs up to a format of 1,500 x 500 mm with electronics.

Thanks to the printed circuits and the direct mounting of the electronics on glass, installation heights of less than 10 mm can be achieved. This technology is used for ultra-flat designer lights, large-format HMIs, light tiles in walls and floors or as fittings for stylish bathrooms. Printed electronics on glass has been part of the Bavarian glass specialists Irlbacher's product range for 20 years. While the solutions were previously limited in format, glass longboards up to 1500 x 500 mm can now be realized. A correspondingly optimized production line now allows not only analogue or digital screen printing of logos, graphic elements or multi-material designs. In the same system, it is also possible to print circuit structures and circuits on the glass. The shape and size of the flat glass can be freely selected, as can the processing of the edges from angular to soft, touch functionalities, haptic elements, EMC protection, invisible windows for IR communication, anti-reflective coating or optical coating of the glass surface. Depending on the application, degrees of protection up to IP68K can be achieved.

By mounting the electronics directly onto the glass, which is itself part of the housing solution, very slim installation heights of less than 10 mm can be achieved. One example of this is the OMLED designer living room luminaires, which are just 9 mm thin, allowing the light to appear to float in the room. Once all the machining and printing processes have been completed, the flat glass is further processed into toughened safety glass. The circuits printed on the glass are then conventionally SMD-assembled and soldered. Further manufacturing processes, such as painting or encapsulating the electronics, the application of fastening solutions through to device construction, logistics and consignment stock are possible on request. UV-resistant, brilliant and chemically inert ceramic ink systems are available for printing, as well as special and design colors or classic CMYK color solutions. If required, Irlbacher provides support with color analyses and conversions to other color systems.