SKZ: Cleaning plastic surfaces with laser ablation

In the newly launched IGF project LIBS-OF, the SKZ Plastics Center is focusing on the combination of laser-induced plasma spectroscopy (LIBS) and laser ablation for cleaning, pre-treatment and quality assurance of plastic surfaces. The surfaces are to be cleaned, analyzed and activated inline in a single process step.

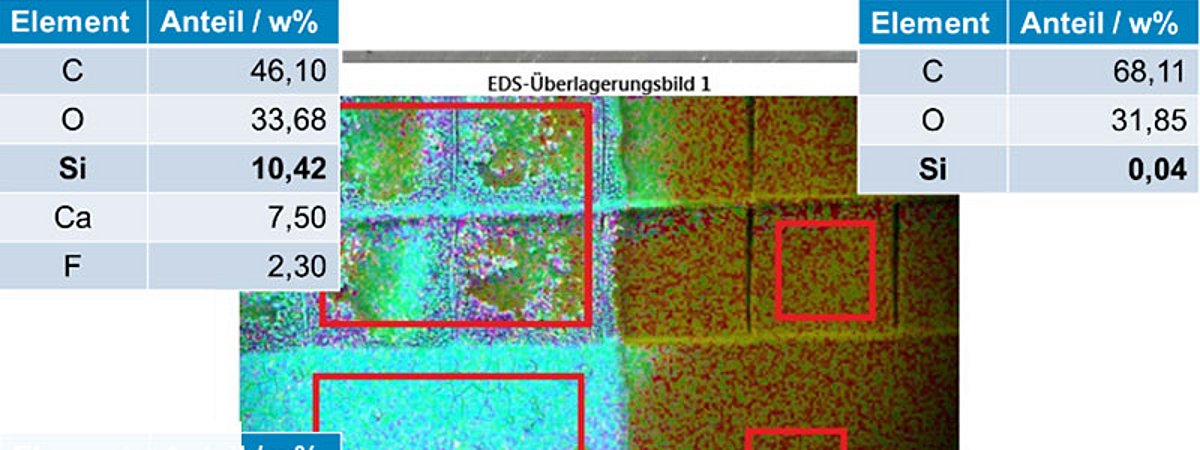

In the plastics industry, the surfaces of components and semi-finished products can become contaminated during production - for example by residues from demoulding aids or release agents. Such residues impair subsequent processes that are aimed directly at the surface, such as printing, painting or bonding. In the newly launched IGF project LIBS-OF, the SKZ Plastics Center is focusing on the combination of laser-induced plasma spectroscopy (LIBS) and laser ablation for cleaning, pre-treatment and quality assurance of plastic surfaces. An ultraviolet (UV) laser with a wavelength of 193 nanometers is used for particularly effective cleaning. This short wavelength makes it possible to break bonds between carbon and silicon atoms. This allows even stubborn contaminants - such as silicone release agents - to be removed, where conventional cleaning methods reach their limits. In addition, the plastic surface is chemically functionalized under the influence of atmospheric oxygen. This creates -OH or other polar groups, for example, which are firmly anchored to the surface. This activation ensures that subsequent processes such as bonding or coating can be carried out directly after the laser LIBS treatment.

Monitoring cleaning with laser-induced plasma spectroscopy

The treatment of surfaces with high-energy lasers carries the risk of over-treatment. Especially in fiber composite technology, too intensive treatment can be problematic: If the reinforcing fiber is exposed on the surface - for example in carbon fiber reinforced plastic (CFRP) components - there is a risk of oxidative damage. This can lead to increased rejects and, in the worst case, to component failure during use. In order to avoid both under- and over-treatment, the cleaning and activation process is monitored inline using laser-induced plasma spectroscopy. The analysis results control the process parameters in real time. In this way, a high cleaning performance is achieved, over-treatment is avoided and process time is saved at the same time. The SKZ invites you to the digital kick-off of the IGF project LIBS-OF on September 25, 2025. Interested companies are welcome to contact Stefanie Grunert. The LIBS-OF project (funding number 01IF23668N) runs from March 1, 2025 to February 28, 2027 and is funded by the DLR Project Management Agency (Society, Innovation, Technology Division) and the Federal Ministry for Economic Affairs and Energy (BMWE).