Innovent: Coated metal implants based on plasma chemical oxidation (PCO)

The international research project "CoatDegraBac" reports in a new publication on the control of the degradation rate of MgCa alloys that were surface-modified at Innovent e.V. using the plasma chemical oxidation (PCO) CaP process.

Biodegradable magnesium alloys are gaining increasing attention due to their advantageous properties, such as avoiding implant removal after the healing phase, and they have suitable mechanical properties compared to conventional biodegradable polymers. Their rapid degradation and corrosion rate are the current limiting factors for their use. The international research project "CoatDegraBac" aimed to significantly reduce the failure of implants made of biodegradable Mg alloys and non-biodegradable Ti-based alloys by specially developed antibacterial and bioactive coatings. For the extensive investigations to be carried out, the coatings developed at Innovent e. V. based on plasma chemical oxidation (PCO) for both magnesium and titanium alloys were made available to the project consortium. Coatings containing CaP as well as those doped with Zn and Ga were developed and made available for this purpose.

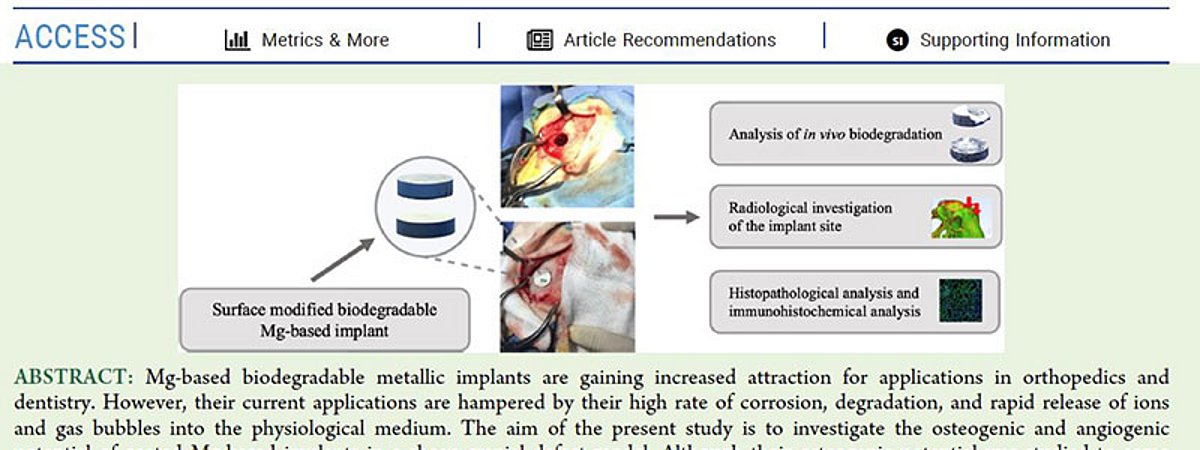

A first summary publication on coated magnesium implants reports on the control of the degradation rate of MgCa alloys surface-modified by plasma chemical oxidation (PCO) with a CaP-containing coating (either doped or undoped with Zn and Ga) and investigated in a sheep skull implantation model. As a result of the in vivo and in vitro experiments, it was demonstrated that such coatings can improve the bone bonding capacity of the implant surfaces and thus accelerate osseointegration, reduce local inflammation and ensure long-term antibacterial properties, significantly reduce weight loss in Mg alloys 4 weeks after surgery, uncoated MgCa alloys had a weight loss of 50% and Zn and Ga doped coatings had a weight loss of < 10%. The results also showed that the surface of the MgCa implants modified with Zn-containing CaP led to increased new bone formation and neovascularization within the defect 4 weeks after implantation. Therefore, an effective strategy was validated in an in vivo large animal model, an important step towards the clinical use of Mg alloys as biodegradable implants.