European premiere of the Supfina Fact belt finish attachment

As one of the leading solution providers for surface finishing, the Supfina team is presenting an innovation to interested parties at this year's Global Industrie in Lyon: the new Supfina Fact superfinishing machine is celebrating its European premiere.

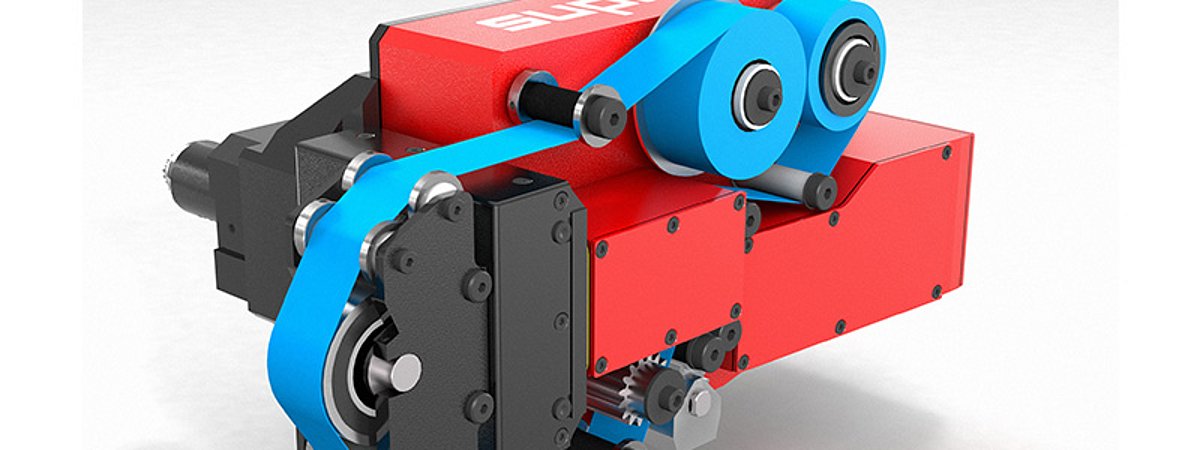

The new Supfina Fact belt finishing attachment, which can be seen at the Global Industrie 2023 trade show in Lyon in Hall 4, Booth C156, is ideal for use in turret lathes with its small, compact design. The surface qualities that can be achieved are far higher than those that can be realized in normal turning. This means that even the highest surface requirements are met. The Fact superfinishing attachment has a small and compact design for mounting on the turret of lathes. The drive for oscillation and belt feed is provided by a central drive from the turret of the lathe, and flushing is provided through the turret to the pressure roller. No additional media connections are required, adaptation is possible on various turret systems. Also possible is oscillation shutdown for twist-free machining using special gearboxes from Supfinma.

A world leader in surface finishing technologies, Supfina offers coordinated machines and solutions for machining tasks ranging from small attachments to complete machining centers with automation: superfinishing, surface finishing, fine grinding, double surface grinding, attachments as well as automation and robotics. As a solution provider, Supfina does not start with machine development and production, but advises interested parties and customers on their individual challenges, validates quality parameters, and even conducts its own studies to develop the appropriate machining solution. Subsequent integration into existing production structures is taken into account, as is the incorporation of future-proof automation and IT infrastructure. In particular, the automation of loading and unloading through to robot-assisted process automation is currently a strong focus of demand. "Our customers are increasingly demanding sophisticated systems for their production processes," explains Dominik Maier, Business Unit Manager, "whether complex automation or upstream and downstream processing, we deliver the solution."