Parts2clean, High Purity, Cleaning Processes: Interview with Gerhard Koblenzer, CEO LPW Cleaning Systems

High Purity is the main theme of Parts2clean 2023 and a major topic in the cleaning industry. Surface Technology Online Editor-in-Chief Oliver Missbach talks about this in an interview with Gerhard Koblenzer, CEO of LPW Cleaning Systems: "High Purity has nothing to do with individual industries, but with processes and mindset in all industrial sectors."

Gerhard Koblenzer: "The focus was set by the trade show organizers. It is "High Purity" - probably a new and important topic for most companies in the industry. Not for LPW. We have over 15 years of experience in this field and are among the pioneers in this segment. Accordingly, together with our partners of the Surface Alliance, we present this expertise on all important national and international core markets and are available at the trade fair with our knowledge for the development of problem-solving approaches in almost all industrial sectors."

Gerhard Koblenzer: "As already mentioned, we have been able to acquire a large as well as broad wealth of experience in this environment over the past 15 years and implement numerous customized solutions for our customers at home and abroad. "Cleaning redefined" may be a leading theme for many visitors, but also for most exhibitors. But in our opinion, for many suppliers and customers it is about finding their way in a changed industry environment and repositioning themselves. The parameters in almost all industries, not only in the classic precision cleaning markets, are no longer the same. Be it due to new mobility concepts or tasks with higher demands on technical cleanliness in, for example, high vacuum and medical technology or sensor manufacturing."

Gerhard Koblenzer: "LPW does not define high purity solely as a task for industrial cleaning technology and certainly not as an industry-specific topic. It is generally about significantly stricter purity requirements. Based on our experience and daily work, it is therefore much more a matter of aligning all processes to avoid and eliminate undesirable contamination right up to the point of use of a component or assembly. This in turn requires a completely different mindset and approach on the part of the user and subsequently also on the part of the supplier of the required cleaning technology. Among other things, the focus is on consistently avoiding re-contamination and cross-contamination, for example due to environmental conditions or the media used. For the plant manufacturer, this means that the cleaning process as such must not introduce any new contamination via the mechanical movements, the media processes or the chemicals. For many years, these new approaches have been standard practice in all areas of our company. From project initiation to implementation in design and production to aftersales through service and application engineering."

Gerhard Koblenzer: "Currently in high vacuum technology and the semiconductor industry. The demand for cleaning solutions is high here and is expected to increase further in Europe, North America and Asia in the coming years. Although not all, many requirements in this area fall into the High Purity division. These are therefore ultra-fine and ultra-high purity cleaning tasks. In addition, there are increasing inquiries from medical technology, sensor and analysis equipment production, aerospace technology, and the automotive industry, among others."

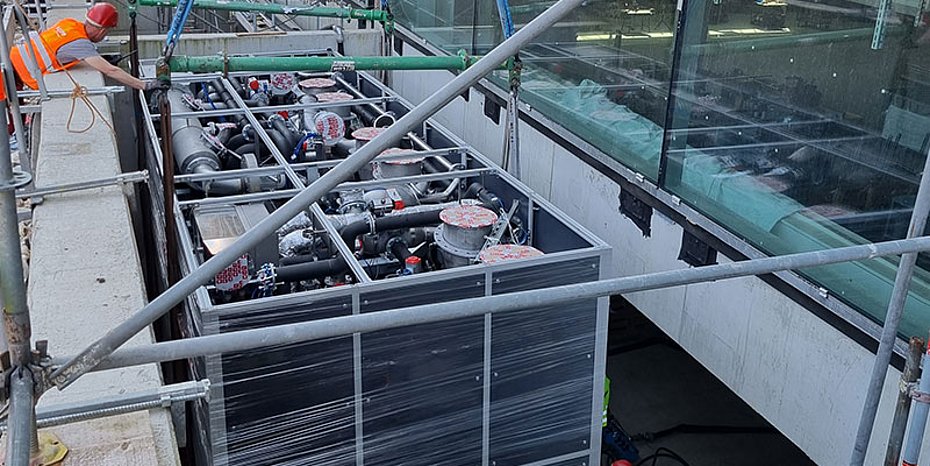

Gerhard Koblenzer: "Many new challenges can be identified. For example, the requirements for technical cleanliness in the process chain are increasing, especially for the suppliers of the major customers. Furthermore, in addition to the supply of suitable cleaning technology, users also expect support in process integration and optimization, validation and the associated monitoring, and often also the provision of contract cleaning capacities. In addition, the complexity and size of components is constantly increasing - while the demands on technical cleanliness remain high. This last point in particular is of great concern to us. XXL components weighing several tons will have to pass through fully automated ultra-fine cleaning processes in the coming years. A simple scaling of the existing processes is not sufficient at the back and front. For this reason, the design-related basic tests are already taking place in our ultra-modern cleanroom-bound test and service center. Implementation in production systems is taking place promptly."

Gerhard Koblenzer: "Cleanliness parameters are always subject to adjustments. Often in both directions, but currently mainly in the more complex direction. This is also the case in ultra-fine and ultra-smooth cleaning. However, we do not see this as the real challenge. Rather, the products are changing in geometry and size. Existing solutions cannot be arbitrarily scaled up or adapted to any geometric shape. New and modified concepts are therefore required. Also in order to be able to guarantee process reliability and cost-effectiveness, among other things. We have been working on this for several years and can now point to successful reference applications for special sizes in, for example, high vacuum technology or special geometric challenges for AM components in medical technology. In addition, there are projects from analytical and measurement technology as well as from the automotive industry environment. It remains exciting."

Gerhard Koblenzer: "Parts and component suppliers in the various high-purity industries also have to deal with completely different tasks in some cases and with the fact that certain cleanliness specifications are currently difficult or impossible for them to achieve with the existing cleaning technology and production processes. This is because the requirements are generally not only defined by particle size and gravimetry. New categories are being added. Keywords here are, for example, filmic, molecular, atomic, toxic or ultra-fine particles. Often also in combination with banned substances and that on a molecular or atomic level. In addition, companies often have to undergo monitoring as part of validation. And that is usually new at this level. So, as a cleaning equipment manufacturer, you are under a double obligation. In addition to a suitable cleaning technology solution, we also have to provide service and consulting in dealing with the new tasks. In doing so, it is important not to overshoot the mark and to take the path step by step. This can also mean that we, as LPW, take over contract cleaning for a transitional period and continue delivery to the customer."

Gerhard Koblenzer: "The presentation is about highlighting the topic of high purity as a mindset in the process as well as the requirements for the user and equipment manufacturer. Because the whole industry talks about high purity and actually means high vacuum technology in the semiconductor segment, which in Europe is essentially characterized by large customers such as Zeiss SMT and/or ASML. However, as discussed earlier in this interview, this view falls short. In practice, high purity affects almost all high-tech segments and that worldwide. The respective cleanliness specification in interaction with the individual component properties forms the guideline.

Market players like to refer to High Purity as the Mount Everest of industrial cleaning technology. This comparison implies that a fixed and measurable goal in the form of a summit is in sight. However, this does not apply here in any form. In reality, it is a continuous process that must adapt to ever-changing requirements, at least in the years to come. The LPW team has reached many supposed peaks over the past 15 years, only to find that a new and higher peak has emerged behind them."

Gerhard Koblenzer: "Of course, we are all feeling the decline in the procurement of capital goods in the environment of the classic automotive industry and mechanical engineering. In addition, relocations of production to other European locations are still taking place. This is a trend that has been discernible since the middle of the past decade, has begun noticeably in 2019, and is far from over. In addition, the fundamentally recessionary mood and high financing costs are having an impact on the propensity to invest. As a result, there is a lack of planning certainty and confidence in new technologies. This is reflected in the order intake of almost all capital goods manufacturers. Nevertheless, there are trends that are becoming established. Additive manufacturing, for example, has become an integral part of our daily work in plant engineering, but also in contract cleaning in particular. Speaking of contract cleaning, the demand for the "cleanroom-based cleaning" service is growing steadily."

Gerhard Koblenzer: "An important topic. From our point of view and based on our internal approach, the following measures, for example, make sense: The integration of cleaning technology into the existing building and machine infrastructure. In addition, pre-processes can be optimized to reduce the effective dirt load and thus cycle times in the cleaning process can be reduced. This reduces energy and resource requirements immensely. Suitable monitoring systems provide good support here."

Contact

LPW Reinigungssysteme GmbH

Industriestrasse 19

72585 Riederich (Germany)

P.O. Box 11 64, 72585 Riederich

Phone: +49 (0)71 23 - 38 04-0

E-mail: info@lpw-reinigungssysteme.de

www.lpw-reinigungssysteme.de

About LPW Reinigungssysteme GmbH

LPW Reinigungssysteme GmbH is one of the leading suppliers of high-quality systems and process technologies in industrial component cleaning with aqueous media. The systems are used in the mechanical engineering, automotive, aerospace and general industry sectors, among others. With its High Purity division, LPW is also a sought-after partner in sectors with fine and ultra-fine cleaning tasks, such as the medical technology, optical and semiconductor industries.